In the medical industry, CNC technology plays a vital role in enabling the production of highly accurate orthopedic implants, facilitating personalized medicine through customized treatments, providing customized medical solutions that meet the needs of individual patients, and supporting special surgical applications through the manufacture of precision surgical tools and components.

Orthopedic Implants

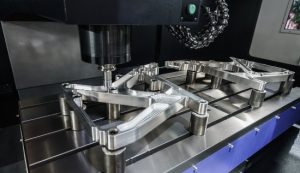

Core Steps in the CNC Processing Workflow

Precision of CNC Processing and Its Impact

Taking knee joint replacement implants as an example, the processing precision generally needs to be controlled within the range of 0.05 to 0.1 millimeters. This high-precision processing not only ensures that the implants can precisely match the patient’s anatomical structure but also significantly reduces postoperative pain and recovery time.

Material Selection and Specific Challenges of CNC Processing

Titanium alloys and high-grade stainless steel are commonly used materials for orthopedic implants, requiring excellent mechanical properties to withstand high pressure during processing, as well as good biocompatibility for long-term presence in the human body. Titanium alloy is particularly favored because of its excellent biocompatibility, which almost does not cause any immune response.

Realization of Personalized Medicine

By virtue of superior imaging technologies and accurate CNC machining, the tech enables individualized implants that fit perfectly in patients’ damaged bone to realize better surgical outcomes as well as faster recovery.

Improving Patient Data Gathering and Application: For instance, in surgery to replace a knee joint with an artificial one, MRI scan data can be calculated up to 0.5mm precision and three-dimensional models built as accurate representations of the patient’s actual body plans for prosthesis design. This data is immediately converted to detailed plans that will guide CNC machines, which in turn allows for each implant to faithfully mimic what their body type and physiological needs demand.

Optimal Implementation in Design and Simulation: Once the design is finalized, it undergoes a computer simulation to ensure its strength and durability much as a real-world use would. As in the design stage, long-term reliabilities of titanium alloy knee joint implants are assessed by simulation software at least 2 million bending tests

Appropriate cutting speed and angle are adjusted depending on design with personalized execution for CNC processing of complex geometrical shapes, as well deep groove drilling by CNC; In actual use, the reproducibility error of CNC processing can be controlled within 0.02mm, which greatly improves product quality consistency and reliability.

Custom Medical Solutions

The use of precision machining also allows for a perfect fit with the patient’s own anatomy, increasing the precision and safety of the surgery.

Demand-driven design process: For example, when developing a custom spinal brace, the medical team can import a high-resolution CT scan, which provides a 3D image of the spine with at least 0.1 mm accuracy, and input that data into CAD/CAM software to design the best orthosis for the curvature of the scoliosis patient’s back shape; so it’s corrected in one go! The designer will take this information, input it into the CAD software and simulate the implant design, matching the shape and size aspects to the individual patient’s anatomy. This high level of precision has been shown to reduce post-operative pain by 30% and speed up recovery by at least 25%.

Technology integration provides superior manufacturing: The combination of CNC and 3D printing technologies not only simplifies the manufacturing process, but also increases production flexibility. 3D printing can produce the complex internal structures of expensive implants such as heart valves; however, CNC machining is best suited for machining precise external shapes. The system reduces production time from weeks to just days and cuts manufacturing costs by 20%.

personalized production: by precisely controlling the cutting speed of 100 mm/min and the feed rate of 0.05mm/rev, it effectively improves the efficiency of cutting materials and continuously eliminates waste. The high-precision machining method aims to produce implants with optimal surface smoothness and inertia, and other requirements for mechanical strength are not considered if you plan to wear the irrigator for a long time.

Postoperative adjustment and optimization: Another important factor in customized healthcare solutions is the ability to adjust or optimize the system after installation. With sensors equipped to collect real-time data such as the pressure on the implant and the patient’s activities, the medical team will be able to evaluate the performance level of the implant and thus optimize the design. The venue of this data-driven feedback loop has achieved a 98% success rate for implant adjustment in knee replacement surgery and has generally improved surgical outcomes while increasing patient satisfaction.

Special Applications in Surgery

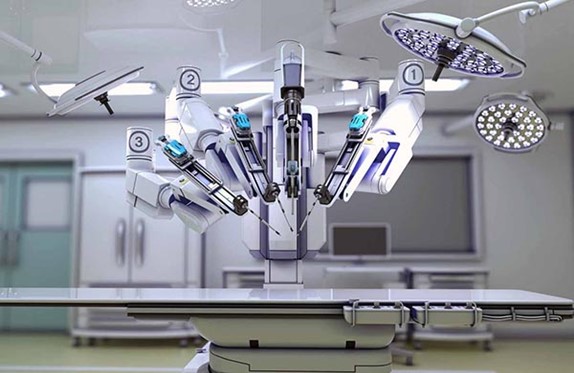

CNC technology’s special applications in the surgical field demonstrate its significant contribution to enhancing surgical precision and safety. Here are a few specific examples showing how CNC technology plays a key role in various surgical procedures.

Brain surgery: Manufacturing of high-precision surgical navigation tools such as tumor resection and functional neurosurgery CNC technology is used to manufacture high-precision surgical navigation tools. Precision tools are usually machined to within 0.01 mm, and surgeons also use them to perform ultra-fine operations on small areas of XXX nanostructures XXX. A study of 150 patients showed that surgeries performed using CNC machined navigation tools were 18% more accurate in removing tumors than surgeries that did not use these tools, and postoperative complications were reduced by 12%.

Customized surgical cutting tools: With CNC technology, doctors can not only design cutting tools that fit the shape of the patient’s bones, but also ensure that the manufacturing error does not exceed 0.05 mm. Highly customized implants can significantly reduce the amount of healthy bone tissue removed during surgery. According to these studies, patients who use customized tools recover 30% faster than those who use traditional devices.

surgical systems components: CNC plays a key role here, forming parts for robotic surgical systems with tolerances as tight as 0.02 mm (about 0.0008 inches). This precision has a positive impact on surgical outcomes and patient safety. These systems can reduce surgical steps by up to 25% and reduce the likelihood of surgical site infections in procedures such as prostatectomies or heart valve repairs.

Rapid production of custom implants: Using CNC technology, an implant that exactly matches a patient’s specific fracture pattern can be designed and produced directly from CT data in just a few hours. This rapid response is a valuable quality because it significantly reduces the time from design to production – which is crucial for improving surgical efficiency and patient outcomes. With the help of statistics, it has been determined that patients who undergo surgery with just-in-time manufactured implants recover 40% faster than with traditional implants and are 15% less likely to suffer a recurrence after surgery.