CNC technology revolutionizes aerospace manufacturing by enabling high precision, increasing efficiency, and allowing for the production of complex components with excellent material utilization. It offers unmatched flexibility and repeatability, supporting innovative designs through rapid prototyping, thus enhancing performance and reducing costs.

Improving Manufacturing Precision

CNC technology enhances precision in aerospace manufacturing by allowing extremely accurate tool positioning and speed control, reducing errors to micron levels and ensuring component consistency.

Precise Control of Tool Position and Speed

Adjustments can be made dynamically during the machining process to ensure accuracy up to ±0.001 inches. For example, when machining aircraft turbine blades, the positional accuracy of the cutting tool is usually required to be controlled within ±0.0005 inches to ensure that the aerodynamic characteristics of each blade are completely consistent with the design.

The Practical Impact of Manufacturing Precision

Taking aircraft engines as an example, the high precision machining of components makes the engine combustion more efficient, which can improve fuel efficiency by up to 5%. Additionally, precisely manufactured components reduce early wear caused by vibration or mismatch, thereby extending the maintenance cycle of the aircraft. It is estimated that maintenance costs are thereby reduced by 10% to 20%.

Data Support for Enhanced Manufacturing Efficiency

With CNC technology, the time to manufacture the same quantity of aerospace components has been reduced by about 30%, and the product qualification rate has increased from the original 95% to 99.5%. This increase in efficiency reduces material waste and allows more parts that meet specifications to be produced in a shorter amount of time.

Increasing Production Efficiency

CNC machines streamline aerospace manufacturing by operating continuously with minimal downtime, significantly reducing the production cycle and associated labor costs.

Enhancing the Efficiency of the Production Process

For example, the traditional manual machining of complex aircraft engine components, if conducted in separate operations, can take several weeks to complete; the advent and use of CNC technology eliminate this time calculated per order, requiring only a few days instead.

Reducing Errors Caused by Manual Operations

Before the adoption of CNC technology, the error rate in manually manufactured aerospace parts could be as high as 5% to 10%. With CNC technology, the error rate can be reduced to below 1%.

Reducing Production Costs

In terms of costs, CNC machining can reduce production costs by about 20% to 30%. For instance, in the production of aircraft structural frame components, using CNC machining, the average manufacturing cost per component has been reduced from $500 to $350.

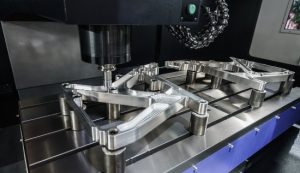

Machining Complex Components

CNC allows for the production of aerospace components with complex geometries that are impossible to achieve with traditional manufacturing methods, thus enabling more sophisticated designs and functionalities.

Easily Handling Complex Geometric Shapes

For instance, integrated aluminum frames or complex aerodynamic surfaces of spacecraft require extremely high machining precision. Using CNC machines can achieve a precision of ±0.0005 inches, whereas traditional methods can only reach up to ±0.01 inches.

The Key Role of Machining Complex Components

Take the production of airplane engine turbine blades as an example; previously, manufacturing these blades could take several weeks, but with CNC machining, the time can be reduced to just a few days.

Practical Application of CNC Machining

An airline, aiming to improve the combustion efficiency of its jet engines, needed to produce combustion chamber components with very complex internal channels. CNC technology increased the precision of these combustion chamber components by 40%, and reduced the manufacturing time for each component from 72 hours to 18 hours. The overall production line output increased by 30%, while production costs decreased by 25%.

High Material Utilization

CNC technology optimizes material use by minimizing waste during the machining process, crucial for expensive aerospace materials like titanium and carbon fiber, reducing overall manufacturing costs.

The Advantages of Material Utilization

For instance, in the fabrication of aircraft engine turbine blades, skillful CNC machining allows optimizing nearly every piece of titanium alloy and usage reduction to 30% is minimal materials waste.

Reducing Material Waste

CNC of an aerospace company which manufacturer composite material wings, reduced its per-wing-of-material by 30%, from $4k to only $2.8K – with overall better quality & consistency in their materials and components as well!

Increasing Production Efficiency and Reducing Costs

For example, in the production of aluminum alloy spacecraft structural components, CNC machined parts save time on material preparation and post-processing alone, thereby shortening a six-week manufacturing cycle to just four weeks or more (increasing production efficiency by 33%). The time saving from this not only speeds the market launch of its products but also scales back labor and equipment costs.

Flexibility and Repeatability

CNC machines offer the flexibility to quickly switch between different production specifications and consistently reproduce parts with high precision, essential for maintaining quality in aerospace manufacturing.

Benefits of More Production Flexibility

For instance, a factory that can switch from one day making molds for an aircraft wing to the next churning out engine components. This changeover is faster and a much more flexible alternative to conventional manufacturing techniques.

Quality Repeatability in Production of Products

Every component in aerospace manufacturing needs to be consistent within a tight precision tolerance of ±0.0005 inches (12,7 μm) between continuous production processes with accurate dimensions and tolerances that only CNC technology can provide

Overall Benefits

A huge aerospace enterprise provided a clear description, after the application of CNC technology followed their products defect rate reduced from 3% to less than 0.5%, production efficiency increased by over 40 percent, this is greatly improve its competitiveness proportion and market share.

Supporting Innovative Design

CNC technology supports innovative aerospace design by facilitating the rapid prototyping of complex parts, allowing for quick iteration and refinement of designs to enhance performance and efficiency.

Inventive Design Execution:For instance, using CNC technology allows us to generate aircraft components with aerodynamic characteristics that are ideal for flight properties and topography of shapes can greatly stimulate the efficiency and performance before any plane ever takes off.

Faster Prototyping:For example, an aerospace company employed CNC to quickly manufacture prototype parts for a new engine in 24 hours compared with several weeks.

Benefits of Innovative Design:More accurate and effective design, overall weight reduction through cargo optimization can lead to fuel costs savings with a substantial cost of airlines.