Sheet metal processing is the process of shaping and forming metal sheets into various shapes and parts through methods such as cutting, stamping, bending, and welding.

Cutting and Blanking

Common cutting equipment includes shears, laser cutters, and plasma cutters. High efficiency: metal plates can be processed at a rate of 20 meters per minute.

Laser cutters generally have power ranging from 1000 watts (W) to 6000 watts, with precision reaching 0.1 millimeters or even higher, significantly surpassing the precision of traditional shears.

Plasma cutters can cut 3 feet per minute, with instantaneous speeds reaching 1500 millimeters, characterized by fast speed and good cutting quality, typically handling between 100,000 to 200,000 pieces.

In the blanking stage, the ability to ensure such cutting precision directly affects the quality and efficiency of subsequent processing. For example, in automobile manufacturing, each car requires 1500 to 2000 stamping parts, and an error in any part can affect the assembly process of the entire vehicle.

The assembly line production model emerged in the 1920s, pioneered by Ford Motor Company, which applied this production model to the blanking and assembly processes of automobiles. Edison once said, “Efficiency is the measure of success.”

The cost of laser cutting generally ranges from 300 to 600 RMB per hour. Although the initial investment is higher than traditional shears, the return rate is significantly increased.

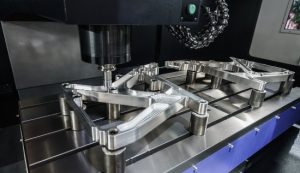

Bending and Forming

Using external force to bend and shape metal plates into various angles and shapes. Bending machines have power capacities ranging from 100 to 500 tons, capable of processing steel plates below 12mm very well.

For example, in automobile manufacturing, each car has approximately 1000 bending parts, requiring high processing precision with an error margin less than ±0.1mm. The efficiency of the bending process is directly related to the completion rate of the automobile production cycle, with bending machines typically handling 300 to 400 workpieces per hour.

CNC bending machine prices range from 500,000 to 2,000,000 RMB per unit. Despite the high initial investment, their precision and automation significantly reduce labor costs and rework cycles.

Metal plates are pressed using machines and stamping dies. In the aerospace industry, fuselage panels of aircraft are extensively manufactured using stamping technology.

Roll forming is a new type of non-cutting processing method that can shape metal plates (cut workpieces) into thin-walled rings, conical cylinders, or other rotating bodies.

Many manufacturers believe that “quality is the lifeline of the enterprise.” Roll forming not only increases the marketability of products but also extends their lifespan. For example, in the home appliance industry, the forming quality of washing machine housings and refrigerator molds directly affects the lifespan and user comfort of the products.

CNC bending: hourly costs range from 500 to 1000 RMB. CNC bending is a better process for mass production with a high return on investment.

In the last century, Japan’s manufacturing industry advanced rapidly in production efficiency with advanced production technology, placing bending and forming at the highest level globally.

There are various welding methods, including arc welding, spot welding, and laser welding. Arc welding currents can be as low as 50A, approximately equivalent to 1/4 inch of metal, but can go up to 500A.

Spot welding is an efficient welding method, with each spot taking 0.2-0.5 seconds to complete, handling 5000-80000 spots per hour. This indicates that multifunctional/simple objects are suitable for mass production, performing multiple depths of fusion in several instances while minimizing substrate layer deformation. For example, automotive manufacturers may require thousands of welds for the car body.

Welding and Assembly

As of 2017 and beyond, laser welding power ranges from 1000 watts to at least 15000 watts, with welding thickness within the above range (approximately 2 millimeters to 4 feet or even thicker), provided CW mode and beam delivery technology/mechanical arms are used. In the aerospace field, the wings and fuselage structures of aircraft are mostly welded using laser welding technology.

The phrase “details determine success or failure” is aptly illustrated in welding and assembly. For example, in bridge and building steel structures, welding quality requirements are particularly higher than general specifications, as any welding issues can lead to more severe safety accidents.

The precision and speed of assembly are directly related to the production cycle and cost. In consumer electronics manufacturing, the speed and accuracy of robots are crucial; assembling a smartphone typically takes half an hour to an hour, involving nearly hundreds of parts that require precise alignment.

Toyota is renowned for its lean production model, capable of producing 60 cars per hour, setting industry standards in process productivity and quality control.

The cost difference between arc welding and laser welding is typically about fivefold, with traditional methods averaging 30 dollars per hour, reaching up to 100 dollars per hour, while the cost range for auxiliary metal structures is high (about 200-500 dollars per hour). Nikon, a well-known manufacturer in the world’s most advanced countries, has annual sales exceeding 100,000 units, with over 80% of microscope parts processed using CNC technology.