Heat Treatment Technology Improvement

By adopting advanced techniques that precisely control temperature and cooling rate, the tensile strength of metal materials has increased by 20% to 30%. For example, using isothermal quenching technology, the hardness of steel can be increased from 40 HRC to above 60 HRC.

Renowned materials scientist J.R. Davis pointed out that modern heat treatment technology can double the fatigue life of steel. For example, in the manufacturing process of turbine blades, using vacuum heat treatment technology can improve the oxidation resistance of the blades by 30%. By adopting advanced induction heating technology, the heat treatment cycle time is reduced by 50%, while energy consumption is reduced by 40%.

Laser heat treatment technology uses a high-energy laser beam to rapidly heat and cool the metal surface, significantly increasing the surface hardness while maintaining the toughness of the core. For example, after the landing gear components of the Boeing 787 aircraft undergo laser heat treatment, their fatigue resistance is increased by 25%, and their service life reaches 15 years.

Use of Nanomaterials

The addition of carbon nanotubes increases the tensile strength of composite materials by 150% to 200%. For example, NASA uses carbon nanotube-enhanced composite materials in rocket shells, reducing the weight by 30%.

The hardness of nano-ceramic materials is 30% to 50% higher than that of traditional ceramics. For example, in the manufacturing of cutting tools, the lifespan of tools made from nano-ceramic materials is doubled, and the cutting efficiency per hour is increased by 40%.

Elon Musk once stated, “The application of nanomaterials is a major breakthrough we have achieved in the field of materials science.” Tesla uses nano-silicon materials in electric vehicle batteries, increasing the energy density by 20% and speeding up the charging rate by 50%. In the marine environment, the use of nano-coatings on hull surfaces improves corrosion resistance by 60% and extends the service life by more than 10 years.

By embedding nanoparticles in concrete, the compressive strength of concrete is increased by 25%. Building engineer John Smith pointed out, “Buildings using nanocomposite materials are not only stronger but also more effectively resist natural disasters like earthquakes.” For example, in some high-rise buildings in San Francisco, the use of nano-concrete significantly enhances structural safety.

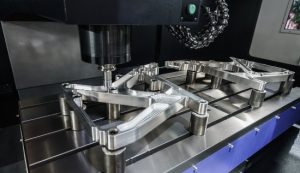

Surface Treatment Technology

Using ion implantation technology, the surface hardness of steel is increased by 30% to 50%. For example, the automotive industry uses this technology to extend the lifespan of components by 20%.

Renowned materials engineer Li Ming once said, “Surface treatment technology is one of the keys to improving material performance.” For example, after titanium alloy components in the aviation field undergo plasma spraying treatment, their fatigue resistance is increased by 40%.

In marine engineering, ships and offshore platforms use electroplating technology to prevent seawater corrosion. For example, a marine engineering company extended the lifespan of equipment from 10 years to 15 years using electroplating technology.

The electronics industry uses chemical vapor deposition (CVD) technology to treat silicon wafers, increasing the conductivity of the treated silicon wafers by 25% and the computing speed of chips by 15%.

Laser surface hardening technology rapidly heats and cools the metal surface using a high-energy laser beam, significantly increasing the surface layer hardness. For example, a large machinery manufacturing company uses laser surface hardening technology to increase the hardness of gears from 45 HRC to 60 HRC, extending their lifespan by 30%.

Surface treatment technology is also common in daily life. For example, high-end cookware brands use anodizing technology to treat aluminum cookware, increasing the surface hardness of the cookware by 35%.