The price of a DMG Mori CLX 350 depends on its features, material costs, market demand, and the cost of additional accessories and customization options.

Machine Specifications

The DMG Mori CLX 350 remains one of the most striking machines in the market. Not only is the machine characterized by a durable construction, but it is also the impressive suite of capabilities that it offers . To start, it is vital to look at the machine’s specifications, which is, indeed, one of the core determinants of the machine’s costs and the critical aspect for all precision manufacturing needs.

Core Features

Spindle speed is categorized as a core feature, ranging up to 5,000 rpm, which can be sufficient for diverse demands for either high-speed or high-precision manufacture. An equally important core feature is that of a tool-holding capacity, which in this case, is a 12-station turret . Tool holding allows for rapid change, which can minimize downtime and allow high levels of productivity.

Advanced Features

Turning to advanced features, the machine similarly does not shy away from innovative solutions. Advanced automation benefits include bar feed and a robot arm for performing part handling, which can contribute to minimal manual labor and high levels of an output increase. Advanced software includes controls, such as the CELOS® interface, which highly contributes to the overall upgrade of user experience and process integration. Remember, that it is the relationship or the synergy between the core and advanced features that position the DMG Mori CLX 350 to be one of the leading machines within its class, and these features are what justify the cost of investment. Whether for the spindle’s stable torque for heavy cutting or the precise control for intricate designs, this machine is clearly capable of almost anything in CNC machining.

Manufacturing and Material Costs

Now, if we were to dive into the financial anatomy of the DMG Mori CLX 350, we would have to look at its manufacturing and material costs. Indeed, this information would contain the machine’s market price and disclose its actual, unmodified cost. Its noteworthy features would be broken down into displays of sheer expenses on the materials and production of such equipment.

Quality of Materials

First of all, the quality of the metals used in the production of the DMG Mori CLX 350 cannot but be flawless. The product’s materials are not only extremely sturdy but also perfectly precise on the back end. Specifically, titanium and aerospace-grade aluminum could be used in its manufacturing, raising the price by up to 20%. The starlet of materials that goes into each machine is calibrated based on the market’s metal index at any point in time.

Production Techniques

Another major expense in production techniques includes the machinery used and the technicians controlling the process. For instance, a single unit could undergo the five-step procedure:

Computer-aided design for absolute precision in manufacturing the equipment.

Computer-aided manufacturing for optimum planning of its production.

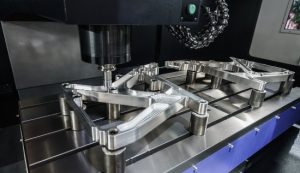

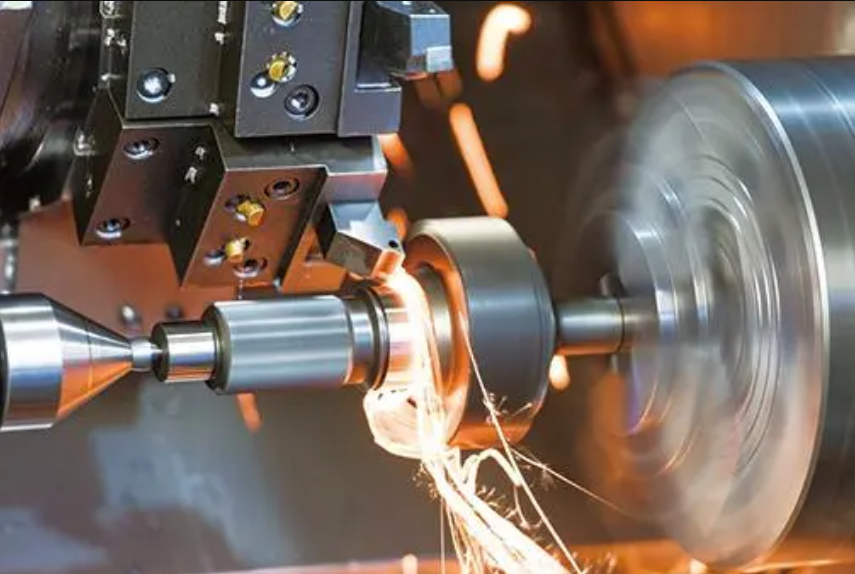

CNC machining to provide flawless material shaping.

In-house quality control procedures, with an error margin of less than 0.005% of defects.

Final assembly by professional and highly trained engineers.

Consequently, waste in manufacturing is down to an absolute minimum, while expenses are down to their lowest limits. Each step is planned and executed seamlessly towards constructing a precision class machine. In general, such high-tech metal usability explains its price in CNC machinery costs.

Market Demand

The forces of supply and demand play tug-of-war in deciding the market value of any product. For the DMG Mori CLX 350, market demands shape how this force moves. Demands, however, are not tied to how many people would buy the product. That would be too simplistic. Instead, the value of this demand is read against ongoing industry trends and the ability the factory has to match that demand.

Supply and Demand Dynamics

When looking at the tug-of-war of supply and demand, one can see that the DMG Mori CLX 350 is not just a machine; it’s a signal of quality manufacturing in the modern era. If the industry requires more intricately manufactured components, the demand for machines capable of this work goes up. If the industry demands more, especially in sectors like high tech, the tag of CLX 350 does as well. It’s economics 101 – high demand and low supply mean that machines could be priced higher.

Pricing of Competitors

And then, there is the eternal competitor. No product can ever exist in isolation; it exists in a market whose every movement must be taken into consideration by DMG Mori. Thus, if a competitor cuts prices, or implements a new technology in its own product, Mori may need to respond price-wise or value-added without increasing the cost. It must take all these considerations into play.

Market demand is the heartbeat that DMG Mori keeps beating continuously. It requires a delicate understanding and careful use over time. One can say that setting the value of the CLX 350 according to the need of the market is the art of turning this demand into something that the customer understands how DMG Mori has excelled.

Additional Equipment and Accessories

The DMG Mori CLX 350’s versatility is one of its dual-use functions, as a variety of additional equipment and accessories allow customizing the machine for any customer. These add-ons are, in some cases, capable of unlocking the machine’s functionality, precision, and required level of automation. Therefore, they affect how much the equipment costs overall.

The difference between standard and optional accessories is quite apparent. Standard accessories are features that come in the base configuration, such as everything needed to set up and run the machine. Optional accessories are not always standard, as they are aimed at improving machine capabilities. For example, a high-pressure coolant system is an optional accessory, but it may range in price depending on the system’s complexity, ultimately increasing the price by several thousands.

This is where things get personal. Buyers have their own needs when it comes to using a milling machine. DMG Mori has details of customer requirements and customizes the products as needed. For example, a customer needs a fixture design for an unusual component. This process is likely to occur as follows:

-

-

Defining the need: A detailed discussion with the client regarding what features of their part require a specific shape.

-

Preparing the fixture: In this step, prototype plans are designed and prepared.

-

Testing: After being tested, the fixture is sent back to the customer with modifications to address any uncovered issues. The customer is then sent three working prototypes before the manufacturing process begins.

-

Producing the fixture and incorporating it into the CLX 350.

-

As a result, although the customization is as detailed and customer-oriented as possible, it can often result in an increase in costs due to this degree of precision. Final costs for a customized milling machine add up to the customer’s expense. Overall, when considering everything that the CLX 350 can turn into with enhancements, the latter doesn’t just add value on its own. Rather, they enhance the value the machine brings to the manufacturing floor. Indeed, it’s a game-changer, a way to achieve an unparalleled level of accuracy and efficiency.