CNC machining hazards include exposure to moving parts, airborne substances, chemicals, extremely loud noises, heat, and vibration. Proper safety measures are essential to mitigate these risks and ensure a safe working environment.

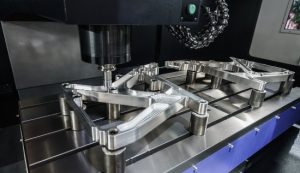

Moving Parts

It is the presence of so many moving parts when CNC machining that can be incredibly dangerous. These moving parts can catch or strike operators (spindles, cutting tools and workpieces). CNC machines have speed and precision, so that accidents can occur rapidly with very destructive results.

Spindles

The CNC machine spindle holds and rotates the cutting tool. High-speed spindles rotate at speeds much higherthan 20,000 RPM. This extreme velocity also turns the spindle into a significant danger if it comes in touch with an operator, wearing some type of clothing like hair, or human body parts. There were at least 3,000 cases of spindle-related injuries reported in the U.S. last year, each involving a range from minor lacerations to severe amputations.

Cutting Tools

Drills, mills and lathes are required for shaping materials properly, which will introduce a tiered system of cutting tools. These tools are powered by mixing and match of high speed, ultrahigh pressure that makes them extremely dangerous. According to a study from the Bureau of Labor Statistics (BLS), cutting tools accounted for approximately 25 percent (%) of all CNC-related injuries. Adequate training and the application of safety guards are required for health-and-safety measures that need to be taken in order to avoid accidents.

Workpieces

Because, apart from the fact that during machining the workpiece is firmly clamped and sewn with a variety of forces. A workpiece that is not securely clamped can act as a missile. These resultant injuries have ranged from severe to death and are often in the form of a flying part fired out of CNC machines. According to data from OSHA, recurring issues with workpiece mis-controls and unsecured parts have resulted in 15 deaths and over 200 serious injuries this year.

Substances In The Air

Airborne Hazards: CNC machining releases a whole range of hazardous substances into the air. Airborne contaminants such as metallic dust, coolant mists and smoke for cutting operations are typical. Metal working fluids may cause skin disease and respiratory issues, as found in a study by the Occupational Safety And Health Administration (OSHA). Each year in the United States, approximately 1.2 million workers are exposed to metalworking fluids and may be at risk for asthma and other respiratory diseases preventing them from working at peak capacity due to illness or long-term lung damage that leaves them dependent on disability benefits (4).

Metallic Dust

The cutting and grinding process in CNC machining makes fine metal dust. It can be aluminium, steel or titanium powder.” Inhaling these particles can lead to health problems like occupational asthma and chronic obstructive pulmonary disease (COPD). According to a report in National Institute for Occupational Safety and Health (NIOSH), workers with exposure to metallic dust have up to 30% higher risk of developing respiratory illnesses.

Coolant Mists

CNC Machining Coolants are used to reduce heat and friction. If these coolants are sprayed onto the workpiece, they can create airborne mists. The inhalation of coolant mists has been proven to cause respiratory diseases aswell and dermatitis. A 2020 study in an ergonomic journal showed that the odds of chronic respiratory symptoms are increased 1.8 times when workers are exposed to coolant mists [4] Having a proper ventilation system as well mist collectores can help to combat this, which goes some way to eliminating the risk.

Smoke and Fumes

High-speed processes like cutting and engraving can create smoke, fumes. These contain a variety of chemicals, many volatile organic compounds (VOCs) and other hazardous air pollutants (HAPs). Chronic exposure to these fumes are a health risk and contribute towards lung cancer as well as other respiratory illnesses. The Environmental Protection Agency (EPA) found that some VOCs can trigger cancer deterrent by up to 40%, according to the EPA. Workers should be protected with appropriate extraction systems, as well as personal protective equipment (PPE).

Hazardous Chemicals

It is not uncommon for CNC machining to go hand-in-hand with multiple dangerous chemicals that put the operators and environment in danger. These chemicals are coolants, lubricant and cleaning agents with potential risks.

Coolants

They are coolants that are required in CNC Machining to minimize heat and friction. These contaminators often involve chemicals such as ethylene glycol and biocides that release formaldehyde. Coolant mists pose respiratory and dermatitis risks – study Coolant mist exposure linked to respiratory issues, dermatitis: NIOSH In 2019 alone, more than 20,000 workers in metalworking industries suffered from skin disorders due to exposure.

Lubricants

The lubricants used in CNC machining cut down on wear and tear caused to tools as well as the workpieces. Mineral oil or synthetic fluids are common lubricants, these can be harmful if inhaled and ingested. Chronic exposure to specific lubricants has been linked in animal studies, with scientific consensus opinion from authorities such as the Centers for Disease Control and Prevention (CDC) concluding that these pose risk of long-term health problems including cancer. A 2020 report details a 1.6 times increased risk of lung cancer among workers in the metalworking industry across all ages (15-64 years) versus reference sitepopulations.

Cleaning Agents

CNC machines are kept clean and accurate with the use of various cleaning agents. They can contain agents with volatile organic compounds (VOCs), such as acetone and trichloroethylene, methyl alcohol. Symptoms of VOC exposure: Headache, dizziness and extra health problems VOCs, as reported by the Environmental Protection Agency (EPA), lead to indoor air pollution and has been associated with liver & kidney damage. There is a documented case where exposure of the liver from trichloroethylene to a worker associated with severe damage for workers; everyone should have made use of local exhaust ventilation and/or full personal protective equipment.

Extremely Loud Noises

As with a great many manufacturing operations, CNC machining environments are often incredibly loud places that put the hearing of workers at risk. Continued long-term exposure to elevated noise levels can cause permanent hearing loss and various other auditory problems.

Noise Levels

Noise levels produced by CNC machines can reach hazardous limits Most CNC machines emit noise at the levels of 80-110 decibels (dB). The National Institute for Occupational Safety and Health (NIOSH) says that exposure to noise levels over 85 dB long-term can destroy hearingcapabilities. According to a 2021 survey by the Bureau of Labor Statistics (BLS), more than 22 million workers in US were at risk from hazardous noise levels.

Hearing Damage

The longer and more intense the exposure, the greater is potential for hearing damage. Workers who are continuously exposed to noise at levels of 90 dB or over for eight hours a day show significantly elevated risk from NIHL. Workplace noise and hearing impairment: A study conducted by NIOSH in 2019 revealed that nearly a fifth of workers (17%) working in the manufacturing sector are suffering from industrial deafness due to workplace noises.

Protective Measures

Hearing conservation programs are necessary. These programs should also incorporate hearing testing, PPE (hearing protection devices including earplugs or earmuffs), and engineering controls to attenuate noise where it is produced. To reduce exposure, NIOSH recommends employing noise barriers or enclosures; and installing sound-dampening materials. One case study detailed a manufacturing plant that cut noise levels by 15dB after it installed acoustic panels and practised good machine maintenance to ensure machinery was never causing excessive sound.

Regulatory Standards

OSHA, the Occupational Safety & Health Administration created permissible exposure limits (PELs) that must be complied with for noise in a workplace. OSHA mandates a PEL for noise of 90 dB averaged over an eight-hour day, but permits exposure up to 115 dba (a program administered under Section XX) if offset by reduced exposures during other parts of the workweek. If noise levels are at or above these limits, the employer must have a hearing conservation program. Meeting these standards is critical for the preservation of worker hearing and long-term health. In 2020, OSHA received more than 2,000 citations for violations of the noise standard that meant most companies needed to pay heavy fines.

Heat And Vibration

CNC machining is known to cause heat and vibration where temperatures can get high enough it could pose a threat both on the machine itself, as well as its operator. It is necessary to be aware of these hazards and how they can be managed in order to have a safe work environment that works well for all.

Heat Generation

CNC machines create a fair amount of heat during cutting and shaping due to the friction that is made from the contact between your tool bits performing the cut versus material itself. In other words, the temperature of the cutting point can go over 1000°F (538°C) depending on material and speed. The heat conduction will be very high such that if one does not take necessary safety measures then burns and other diseases due to excessive heating effects can happen. Many of these were from hot machinery and materials, as there were over 5000 reported cases in manufacturing settings by the Bureau of Labor Statistics for burn injuries at work.

It can also impacts on the accuracy of machining. Parts are displaced by as much as 0.1 mm due to thermal expansion effects, affecting the precision of parts positioned relative to others and causing problems with quality control. To control these high temperatures, it is critical to use effective cooling systems eg: flood coolant or mist coolnants. By servicing these cooling units on regular basis, they are checked from working correctly to avoid odour and other hazards of overheating.

Vibration

In CNC machining, vibration is also a big problem. Over-vibration may affect the quality of products, resulting in rough surface and dimensional mismatch. Their study indicated that the vibration can increase as much as 20-50% surface roughness according to machining conditions.

Operators suffer from Hand-Arm Vibration Syndrome (HAVS) when exposed to vibration for long durations as it results in circulation on the nerves of hands and arms. Worker health conditions associated with HAVS affect around 2 million workers to some extent in the USA, and may cause tingling numbness or loss of grip strength according to Health & Safety Executive (HSE). It will also identify whether workers who are exposed to more than 2.5 m/s² in an eight-hour workday run the risk of developing HAVS.

Mitigation Strategies

This poses significant risks of vibration, which need to be controlled using vibration damping techniques. Vibration can be tackled by materials that dampen vibration, and sharpening cutting edges combine with balancing cutting tools reduces the level of vibrations. This allows for the CNC machines to be serviced regularly and calibrated with the correct vibration stats.

Real-Time Monitoring and Training

Sensors and diagnostic tools enable real-time heat and vibration measurements to monitor, catch problems early. Similarly, the operators need to be trained as how a special kind of excessive vibration and heat is produced by components in stress or at high speed. Implementation of automated monitoring systems for machines has reduced the downtime by machine 30% and improved productivity by +15%.