Choosing the Right CNC Machine Tool

The choice of CNC machine tool is the key to quality and production efficiency. Now let us go into how to choose a machine according to the need of your industry and incorporate detailed data for analyzing performance parameters, yet maintaining lowest TCO.

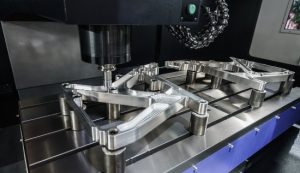

Meeting Industry Needs Precisely

in specific circumstances and industries (eg For space applications for processing of aluminum or/and titanium alloys parts requiring high accuracy-ed very rigid machines. These should have a positional accuracy of ±0.001 mm and repeatability not less than ± 0,0005mm In automotive manufacturing, instead it may be on processing speed and automation for large volume mass production. The cost of a high-accuracy aerospace materials capable five-axis CNC mashufactuer, can be anywhere from $350k-$1.2m depending upon the configuration and additional capabilities you need to add on top of itufigrewScriptongoing along with that

Frequent monitoring of machine performance parameters

Performance Performance parameters include power, speed and machining range. To work with hard materials such as steel or tough alloys, at a least 15 KW spindle power and spindle speed of 12.000 RPM should be installed in high-performance CNC machine Also, size of table bed most frequently found is 1500 mm ×750mm and it defines the maximum workpiece that can be handled by a machine. These technical conditions affect the applicability of the machine and its processing capacity

Technical Support and Services Decoded

The availability of top-notch technical services and support has the ability to greatly help mitigate machine downtimes and ensure that its operating life is prolonged. Important Things to Know About Brands:Find out if the manufacturer can provide rapid on site repairs, and whether it will enter into annual maintenance contracts for its CNC machines For example, maintenance services in machine calibration can regularly be offered for as little money such as 3% of the annual cost to preserve a high level of performance over time.

Total Ownership Costs Broken Down

Operating costs with running, maintenance and power utilization are a few of the considerations recognized as total ownership cost. Depending on usage and power demands a medium-sized CNC machine, for example may costs an average of $3,000 – to $10k.a yr. Annual running costs are Goldilocks in relation to heavier machines: the price of regular maintenance (lubricants, tool replacement and part changes) is just about right at 5% per annum on average.

Programming and Design

During the endless setting of CNC machining, “Programming and Design” precision program writing plays a vital role in making sure everything is high-quality on track to properly cut. Focus on the G codes and M codesthat are accepted by CNC machines, which control all machine movementsimmediately. Newer CAD/CAM software can create Numerical Machining Codes automatically from 3D Models, making the design more precise and efficient.

Programming Dominance

The majority of CNC machine operations use G codes and M codes. An example of this would be for a simple round part, G02 or G03 codes will be required to perform circular interpolation. For example, to fine-tune the circle that has a 50mm diameter of X25it is possible for G02 Y0 I25 J0 where in its programming instruction whose using I and J will denote as deferment center relative starting position any steps. In executing more intricate machining tasks, these basic codes are indispensable.

Advanced CAD / CAM Software Adoption

For high-precision industries, such as aerospace or medical device manufacturing: Tools with advanced CAD/CAM software like SolidWorks or Fusion 360 can produce accurate CNC codes straight from your 3D models. Such software can enable to streamline the process of cutting as they automatically compute and generate perfect paths for cuts therefore decreasing chances of humanerrors. For example, the software can automatically generate a tool path that has lower material wastage and cutting efficiency for an intricate aerospace part than might be difficult to achieve with manual programming.

Accurate Simulation And Path Optimization

The mimicking of cutting procedure has to be done via software before the actual machining. This prevents collision and damage to the tool (including expensive or irreplaceable materials). For instance, Mastercam simulation allows you to simulate the full machine cutting in order not only allow for fine tuning of parameters like spindle speeds 6000 RPM and feeds 500 mm/min which can keep production efficiency up while still keeping quality high.

Adjusting for industry-specific tendencies

The automotive sector is a common ground for these kind of things, due to the fact that such production can also take place on an even larger scale than scale models making programming much more optimized towards program repetition as most parts will need thousands if not millions in identical amateur mistakes. The programming in the production of custom machinery may have to be more variable for one-off tasks. A typical instance, in case of cars engine parts machining workpiece, the tolerance that must be respected by this CNC program will not exceed ±0.01 mm to asseemble perfectly invisible seal and working performance for a periodicals production life.

Actual Machining Steps

In the “actual processing steps” of CNC machining, the machine tool is first set up and the tool is selected, then the programming code is loaded and checked, the cutting is executed and the process is monitored, and finally the finished product is inspected and the machine tool is cleaned to ensure that each step is accurate and correct to ensure machining quality and efficiency.

Prep Your Machine

Prepare your machine well and then test it fully after the machining process begin in earnest. For instance, if the material is aluminum being machined on a cut-operation in that spindle mega and then do coating with speed of 2500 RPM to adapt machining attitude forestation its properties. Choose a tool suitable for the material (example, 10mm Diameter four-flute Carbide End Mill) and set an Initial Feed Rate to about 800 mm/min so that it is efficient yet not damaging to the tool.

Using a byteSending Loading and Verifying the Program

Load the agreed-upon design of CNC program into a control system for your device. Before starting the machine, check both of its paths carefully to make sure there are no errors in their program. Ensure the cutting paths are clear of all fixtures and machine body, as well as setting feed rates for certain operations such fine machining down to 400 mm/min in order improve machining accuracy.

Executing the Cutting Process

Perform the actual cut, continually checking cutting forces and temperatures so they do not become dangerous for proper operation of machine tool and tools. If working difficult materials (e.g steel with carbides), it may go down to 100 mm/min, adding a lot of frequency during the process so coolant fluid can pass through and lower temperature in tool/work piece.

Examination and Review of the Quality Control

When the machining is completed, precision measuring tools are used to measure dimension of machined part. For example, measure with a digital caliper to guarantee that all dimensions fall within the design tolerances (±0.005 mm). If there are deviations, they should be documented and used to adjust the machine parameters or program accordingly so that all future machining runs accurately.

Post-Processing and Cleaning

Lastly Installation wise machine to be fully cleaned, and neccessary maintenance / job work order has performed before giving it for further operation. This includes taking out chips, greasing all moving parts and checking cutting tool condition; tools are being replaced as needed. Doing this ensures that the machine remains precise in its long term operation and runs efficiently.

Common Problems and Solutions

Tool wear, improper positioning of the workpiece, programming errors or even vibrations in a CNC machine are all frequent problems. Correct choice of materials (soft, brittle or hard), accurate firings program, verification and machine adjustment well solve these problems resulting in demanded machining precision and productivity.

Rapid Tool Wear

For example, in CNC machining wear of the tool is a common general phenomenon when milling hard material like stainless steel. In that case, you can choose tools with better material like cobalt or titanium coated tooling which makes the life of your tool about 50% longer. Moreover, modifications in the cutting parameters like slowing down up to 10% the speed of cut and improving cooling can lead to a drastic decrease.

Wrong Workpiece Alignment

Improper workpiece positioning may result in machining sizes being out. Most often, improper fixture installation goes down and aging. This issue can be solved if regular maintenance and checks of fixtures are taken into consideration to maintain their accuracy and stability. High-precision clamps and regular calibrations can not only reduce positioning errors, but also make the machining accuracy higher.

Programming Errors

On one hand bad programming may cause a machine to malfunction or fails in processing, Detailed program checks, and simulation software will be used to verify the machining before cutting it. It is very important the program to be error free before any of it become actual machinings. In addition to the software aspect of reducing human programming errors, training operators in CNC programming languages and how that affects software operations is also key.

Machine Vibrations

During machining./ Vibrations in the machine from the area during processing cause rougher machined surfaces or dimensions that are out of tolerance. Check to ensure the machine is properly installed and leveled, as this frequently causes vibration. Second, appropriate choice of cutting parameters and the proper tool holders can also effectively reduce vibration.