Key factors in CNC machining tolerances include material properties, machine precision, tool wear, operator skill, and environmental conditions. Each element significantly impacts the final dimensional accuracy and quality of machined parts

The Role of CNC Machining

CNC machining Computer Numerical Control machining is undoubtedly one of the cornerstone technologies of modern manufacturing. It enables the precise, automated production of even highly complex parts, which significantly reduces human error and effort. The following points will address its benefits in more detail.

Precision

First and foremost, CNC machining has allowed the industries that use it to become dramatically more precise. This has had perhaps the most obvious benefit in the aerospace industry, where the exacting safety requirements have made the pneumatic turbine ‘s production as precise as micration. More generally, parts created with CNC machining are produced to within 0.0001 of an inch, which is within a few micrometers.

Complexity

CNC machining allows for highly complex and intricate geometries, many of which would be nearly impossible to manufacture through other methods. This has been particularly valuable in the medical industry, where custom prosthetics and other equipment must be manufactured. A good example of this is shown in the video about the custom dental implants that are precisely constructed with a CNC milling machine

Speed

At the same time an invaluable part of CNC machining that complements the other two beautifully, the relatively high speed of automated machining has made it possible to scale up the production to the levels unheard of in its past. Especially in the automotive industry, one CNC cutter can mass-produce thousands of engine components over a short period of time. They will not have the deviations that hand-made parts might have, which ensures the quality and longevity of the final product.

Cost

Finally, while the initial investment into CNC machining is relatively costly, overwhelmingly, the companies using this technology benefit significantly from the reduced reliance on manual labor and lower error, which reduces their production costs overall. They also waste fewer materials, which is relevant to the industries like ship-building, which uses expensive materials such as titanium.

Impact of Material Selection

The choice of materials under CNC machining is arguably the most critical factor that will directly influence the tolerances, quality, and overall success of the created parts. The reason is that two different materials used under the otherwise same circumstances will have direct impacts on the efficacy of the procedure and the precision of the results themselves. For instance, some materials will have different machinability within the same system, which means that the tolerance of the bits and types of tools used, as well as how hot they can become, will be directly impacted by the strength or hardness of the material. Therefore, the following discussion will detail the main ways in which this choice has an influence on the final product.

Material Properties and Machinability

Machinability refers to the characteristics of a certain material to be cut and shaped without excessive wear of the tools and the product itself. As such, different materials will react differently under the same circumstances, which can have direct effects on the series of cuts that is being made. Aluminum has excellent machinability, resulting in the soft material being able to be molded and shaped at high speeds without significant forces affecting the tools. In contrast, while superior in terms of hardness, strength, and corrosion resistance, titanium has terrible machinability, requiring a specific bit and heavy coolant to maintain the desired speeds and tolerances.

Thermal Expansion and Stability

The material also has significant effects on thermal expansion and the stability of the created parts. Steel expands much more under heat than ceramics or composites, which is why high-speed efficient cutting is largely impossible, even within strict temperature and tolerance ranges. On the other hand, if the selected material is unstable under these circumstances, there may be erroneous cuts and separations of the material which will not be ideal for the final application.

Impact on Tool Wear

Finally, the material will have a direct impact on how much tooling wear is possible, which will set via the acceptable tolerance for the standard run, their number, type of tool, and size. If it is a hard material, like stainless steel, the tools will become unusable very quickly, which means that tighter tolerances will not be possible after certain use. On the other hand, less-forcing materials can keep the standard run finish much longer.

Machine Tool Accuracy and Precision

The degree to which a CNC machine tool is accurate and precise are two of the most important properties that are indicative of its quality and performance measures. These indicators are considered ultimate as they determine closely a CNC machine could reproduce the programmed scales and sizes on an actual workpiece.

Concepts of Accuracy and Precision

The accuracy of CNC machining could be understood as the proximity of the programmable measurements to the actual sizes of the machined workpiece, where the precision is the capability of the given machine tool to repeat the same movements and operations without any dispersion. For instance, if a CNC drill is programmed to make a hole in the workpiece with a diameter of 1.000 inches, the hole accuracy would be estimated based on its actual diameter, while the precision would be hedged on establishing verticality and conicity of the workpiece if the drill has made multiple holes.

Effect of Re-Calibration

For this reason calibration of CNC machine tools should be done on a regular basis. As an example, an aerospace parts manufacturer that specializes in crazy precise machining produces their aerospace tools and parts on their CNC machines, which are calibrated every two months. The schedule of calibration is based on a relatively short period of calibration breaks between the months that are necessary as the evaluator would have to adjust the software and set hardware with the calibration data of how the machine is performing at the ordinary inspection times.

The Role of Servo Motors and Feedback System

Servo motors and the feedback system play a significant role in guaranteeing high CNC precision for the transmission system of a CNC machine that transmits the drive torque accurately, resisting the variational usage and wear is demanded, which requirements perfectly describe the functions of these components. High feed precision of the machine can be achieved particularly due to the quality of the servo motor and the feedback system.

Wear and Maintenance

Another factor that potentially impacts both the CNC machine accuracy and precision is wear phenomena of the machine tools. For instance, the replacement engine spindle bearing wear could cause dispersion in the actual sized of the machined produced, which should be closely observed and controlled. This is the reason why the companies that use CNC machines should stick to the preventive maintenance program that allows detecting the wear of machine components prior they disperse the size of the produced machine parts.

Importance of Design Complexity

The complexity of a design is crucial for the determination of the CNC machining tolerances a part can achieve. While simple parts can be easily produced with high precision and tight tolerances, for more complex designs there are more opportunities for errors to occur during machining, leading to looser tolerances.

Definition of Design Complexity

In CNC machining, design complexity is the complexity of a part’s geometry, including the number of features, their size, and their orientation to each other. A good example of a complex design is a part of a gearbox housing for an automobile engine alloy that our partner produced. Due to the complex internal geometry of the part, it was impossible to machine it just by using standard CNC machines. Such machining is only possible by machines with multiple axes. They allow for the creation of intricate tool paths that would not be possible otherwise, while thin walls can be machined without breaking even at high cutting speeds because the tool is oriented more perpendicularly to thin walls.

Accessibility of Tools

One of the main issues of complex designs is that tools must be able to access all areas of the part in order to perform machining. These tools also need to avoid the part itself, as well as the CNC machine. This is illustrated in the example of the aluminum gearbox’s housing. Even a multi-axis CNC machine had to be specifically modified in order to be able to machine the internal pockets of the part. Use of conventional CNC tools would have broken the thin walls of the part, so the machine had to be precisely reoriented, and then the tool path was determined with the use of CAD/CAM software.

Tolerances of Machining

In general, CNC machining cannot achieve as tight tolerances as additive manufacturing, and the part’s complexity directly affects frequency tolerances it can achieve. Indeed, as some areas of the parts are less accessible, lower feed rates are required as well as a higher degree of control. The example of this is provided by the production of aerospace turbine blades that require high-precision machining. These turbine blades have to achieve the tolerance of +/- 0.0005 inches, and machining these blades requires the use of advanced CAM techniques, with dozens of unique tools, or even hundreds, and frequent tool changes for the whole processing of the part.

Necessity of Setup and Fixturing

Another consequence of the design complexity is that more elaborate setup and fixturing are necessary in order to accommodate the part and ensure its stability during machining. If a part if not fixed well enough, it can move or vibrate in the process, and these deviations will prevent establishment of desired machining tolerances. For instance, in production of complex medical components, custom fixtures need to be designed in order to ensure that neither the part nor the machine vibrates. Not only shorter tools were used in the production of part’s internal blind holes, but also the main portion of the part was clamped with screws during this process.

Measure and Maintain Tolerances

Measuring and maintaining tolerances during the part-making process are among the critical activities in CNC machining. Strategies or tools for monitoring or controlling tolerances throughout the process from prototype development to the delivery of the part must be effectively developed and implemented. The steps may include:

Utilize Precision Measuring Instruments

Maintenance of tolerances may begin with the precise measurement of the tolerance being satisfied. The dimensions of the produced part with respect to the given specifications are usually measured by the use of a wide variety of precision measuring instruments. Examples of such instruments may include:

-

Calipers used for measuring both internal and external dimensions of the produced part.

-

Micrometers for more detailed measuring both internal and external dimensions than calipers.

-

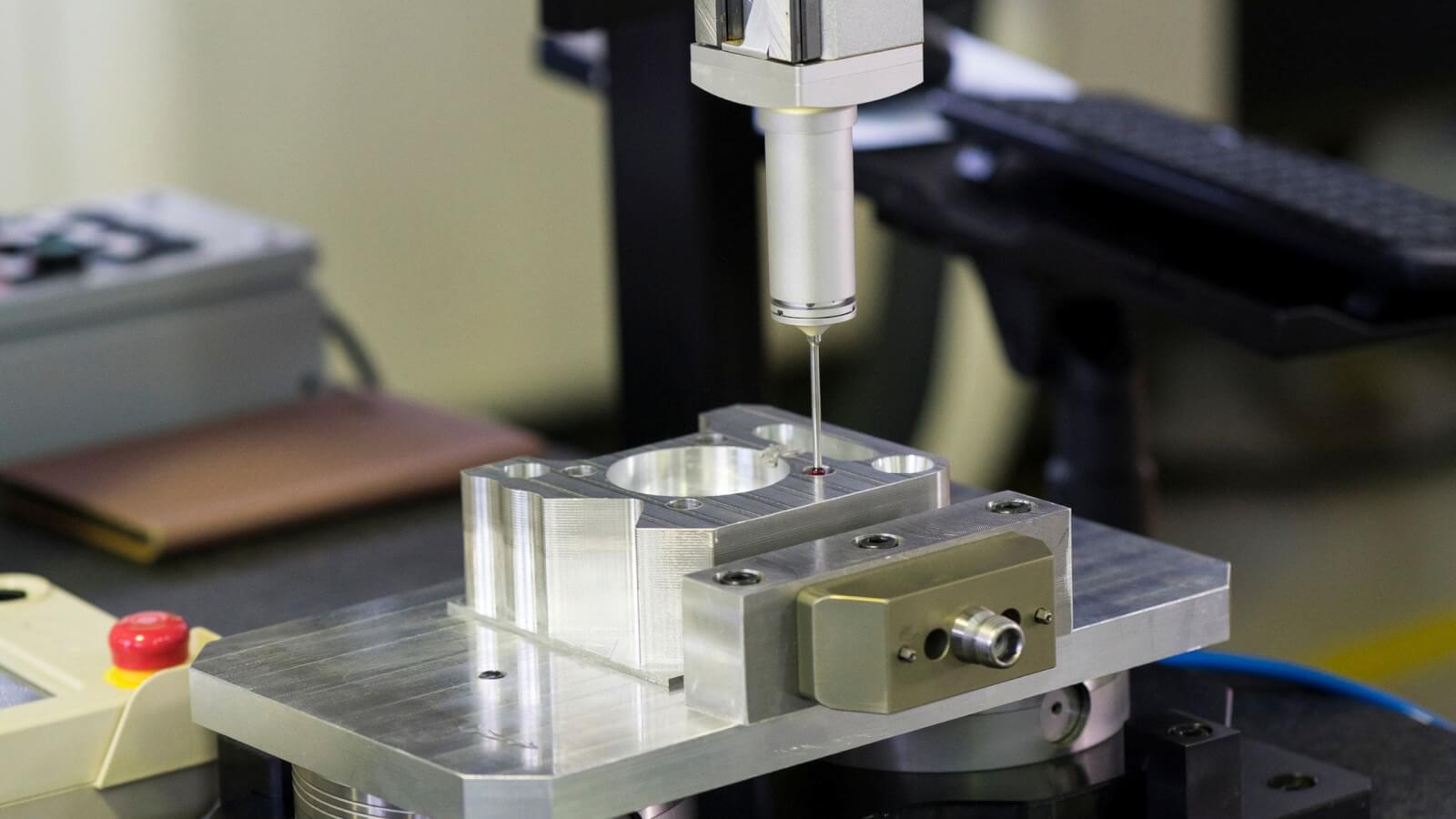

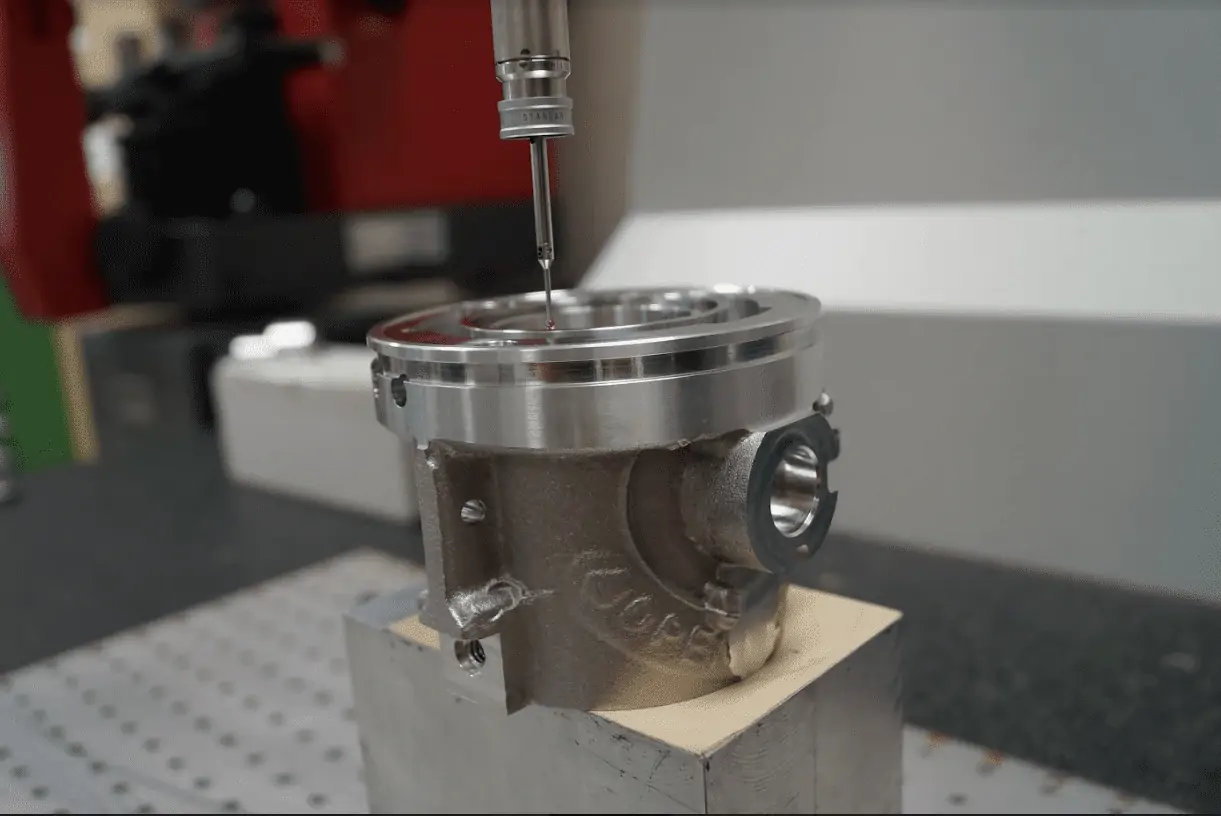

Coordinate Measuring Machines that are in the aerospace industry for checking up and measuring production parts, structures, or castings. The machines may measure parts with the tolerance of up to +/-.0001 of an inch.

Use of Statistical Process Control

Statistical Process Control is a range of statistical measures that relates to measurements of the process ranges. It involves monitoring the process, determining its potential, and maintaining the process to its best capability. SPC involves a variety of measuring parameters, and it effects include reducing the number of specifications-not-faction products, offering standards for rework, and reduction of variances during the machining. In the automotive industry, SPC was essential in the monitoring of CNC operations. Variability was significantly reduced during the process with the resultant improvement of the production parts. The “UNI” labeling was reduced at the process completion, but the parts consistently met the design-related requirements. The labels were returned to the processes with relatively no process problems.

Implement Routine Maintenance

Routine monthly maintenance checks on CNC machines are essential for the maintenance of tight tolerances. The checks ensure that maintained tight tolerances of the machines are scheduled. Huge delays in parts’ delivery are costs which the routine checks prevent. A good example is when a precision engineering firm describes monthly maintenance checks for all its machines and monitoring of the machines to avoid delays in the provision and production of production parts. If during the checks, the spindles and linear guides are worn, production may take place out of given tolerances. However, if the check exposes the worn components early enough, erosion of the spindles responsible for producing products may be done on time before the full spiral leads to failure-causing scrap parts. But replacement and repair of the components will be done without causing the failure of the overall machine system.

Continuous Training For Operators

With the efforts of high-quality maintenance services, the final task involves the operator and the maintenance of the predetermined tolerances. Production of the parts can be maintained within the specifications. Training of the operators to detect small changes in the process leading to tool wear including other changes affecting part tolerance is significant. There is a demand for early processes in the machine’s calibration and separate processes for independent calendars, part formulas, and changes. Maintenance of all these factors ensures the maintenance of end-machined parts in terms of tool calling reducing its liability. An example is using a semiconductor fabrication facility where trainings inform the operators of such processes at levels of single microns being critical.

Adaptation

One of the likely assumptions in CNC machining while maintaining tolerances involves the premises on the frequency with which the product may vary due to natural differences of the used materials from their original or other machined state. Expansive and internally threaded parts of materials based on humidity are common where humidity and other changes lead to material thread changes. Gin cooling eliminates the natural materials’ changes implications in the environment.