CNC machine types include milling machines for versatile shaping, lathes for precision cutting, routers for intricate carving, plasma cutters for metal slicing, and grinders for smooth finishes. Each type is essential for specific manufacturing needs

Milling Machines

Milling machines belong to the equipment of CNC machining, and they are introduced by their ability to form materials with exceptional precision and flexibility. They are used both in the aerospace industry and the automotive sector, including any other sectors where there is a need of precise cutting and where different materials are to be processed.

The kinds of machines which are considered

These appliances are divided into vertical and horizontal types, as well as for complex parts and simple processes. Vertical mills are applicable for complex products including gearboxes, and horizontal mills are good for quick removal of materials of large surfaces, driving on the ways. Vertical milling technology was adopted in 2005 at Boeing, where spacecraft details were produced more effectively, indicating the trend of aerospace industry to more sophisticated technologies used in the manufacturing process.

Key features and advantages

The main feature of this kind of machines is their computer numerical control system and multiaxis capability, running on three and even more axes. These additional axes of movement are used mainly in the case of need of drilling, slot cutting or threading, conditions necessary for making accurate and complicated designs. High precision is achieved, and the tolerance can be as low as 0.0001 inches. This fact indicates their great value for fastening parts and crafting things which are to be capable of withstanding enormous pressure.

Materials which can be processed

Milling machines are good for processing a range of materials, including metals, such as aluminum, titanium, plastic and composites. They are irreplaceable in the medical devices sector, as titanium, with its strength and lightness, in addition to its biocompatibility, is perfect for producing various removable parts which are specified for a particular individual. CNC milling can be also used for titanium prosthetics to make tubercular and antibacterial prosthetic limbs which would fit a particular patient perfectly, being his natural addition.

Technological innovations in the field

The innovation of these machines is associated with their interposition of digital control. CNC features operate via computerized controls and software, including the CNC machining. As a result of the development of CAD/CAM, the precision of the machines has increased significantly, and they now can do things which have been formerly considered as not producible. Developing a more efficient engine in 2017 as a part of a project of a Silicon Valley startup, they were capable of reducing the production time from approximately a year to 9 weeks, achieving such results with the help of modern CNC milling. Operations

Lathes

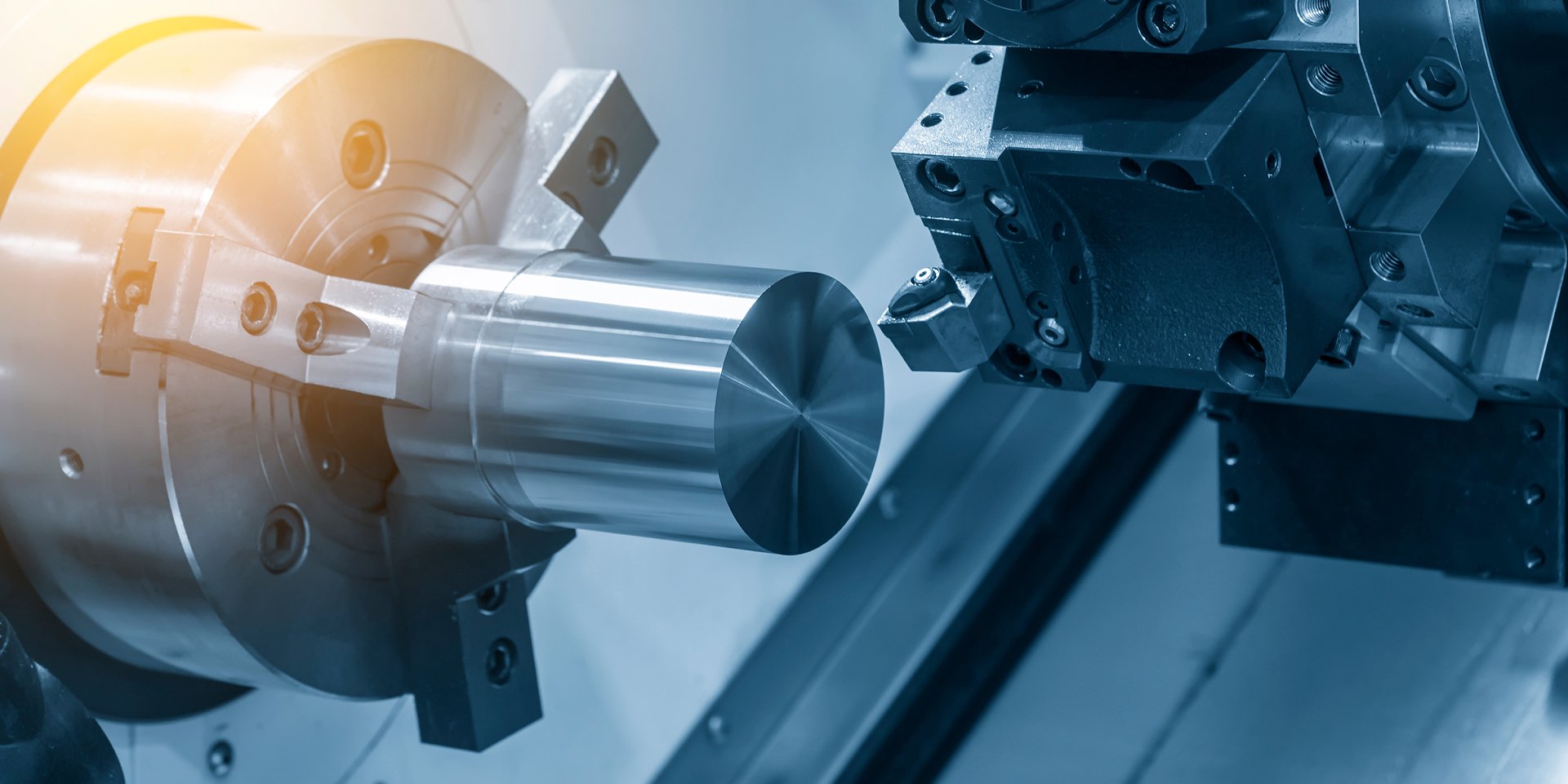

Lathes are the backbone of CNC technology and are mainly used for creating round, or rather, cylindrical parts. It is hard to imagine industries like automotive and aerospace without these machines, which are indispensable in manufacturing precise parts characterized by specific dimensional accuracy and surface finish.

Types of CNC lathes

There are subtypes of CNC lathes, mainly horizontal and vertical. It should be mentioned that horizontal lathes are more popular and are involved in the production of detailed and perfect work on small parts. For the same reason, they are used more widely. However, there are also vertical lathes, which specialize in more massive and heavier details. One of the indicators of the importance of these tools related to the aforementioned industry is the usage of advanced horizontal CNC lathes by a major automotive manufacturer in manufacturing their engines. In 2018, they replaced older machines and achieved the combination of narrow cylinder bore tolerance with an increase in overall engine line efficiency.

Capabilities and features

The advanced capabilities of CNC lathes include live tooling, machines with Y-axis, sub-spindles, which are used for off-center milling, drilling, and tapping, that is, processes that, ideally, require different setups or machines for completing them. For instance, live tooling was crucial for the work of a custom motorcycle shop from California in 2020 in producing parts for unique custom bikes that could not be manufactured on conventional lathes because of their distinctive design.

Compliance and material

As for the material used, there are no such limitations for these machines, and they are suitable and highly used in projects dealing with metals, plastics, composites, and other materials. In 2019, a tech firm specializing in aerospace employed a CNC lathe for producing high-tolerance fasteners made from titanium that secured spacecraft. In 2017, a similar company specializing in the production of custom jewelry manufactured their main product using CNC lathes embroiled with a separate CNC machine, creating some gold and diamond pieces.

Technological advancements

CNC lathe programming has certainly changed alongside the production. Modern CNC lathe machines include software that makes it possible to simulate the whole machining, promoting the prevention and avoidance of errors and material waste. Thus, in 2021, a technology company from NY used simulation to improve both the production of parts for medical devices and the design of those products, reducing time and effort spent on trial runs and testing raw materials.

Techniques

Eventually, operating these machines requires the knowledge of their capabilities, operational principles, and settings that are suitable for machining each definite material or part. The exactness of defining the cutting speed, feed rate, and depth of cut varies and affects the quality and results of products significantly. In 2019, a machine shop from Germany found the right combination and finally began cutting faster by 30%, with products of no worse quality.

Routers

CNC routers are valuable machines capable of cutting hard materials such as wood, composites, aluminum, steel, plastics, and foams. This feature explains their high popularity. They can carry out precise carving, engraving, and shaping tasks quickly, making them a must-have for several industries, such as signmaking, furniture design, and prototype manufacture.

Types of CNC Routers

The available CNC routers are frequently classified into 3-, 4-, and 5- axis variants. In general, the machines have similar capabilities, with some being more efficient in certain tasks. For example, 3-axis CNC routers are good for general 2D and 2.5D routing while 5-axis ones are perfect for complex shapes and convex and concave surfaces with two or more angles, such as three-dimensional objects. The latter type was used in the automotive industry by a major company in 2016. Its workers employed a 5-axis CNC router to make molds for vehicle dashboards that had to be complex and detailed to ensure proper fit. The high speed of the machine makes it vastly superior in such cases.

Key Features and Applications

General benefits of a CNC router are its speed and precision. In 2019, a custom furniture shop in Oregon employed a CNC router to cut out legs for a series of phenomenal-looking tables with ornate bases. The intricate designs of the table were undoubtedly made possible by the router, while any attempt to reproduce them manually would never achieve the same beauty and precision.

Material Properties

The material variety that can be cut and drilled by CNC routers is extensive. A tech start-up used a machine from another company to produce HDPE frames for their drones in 2018. There, I witnessed that the flexibility of the router is defined by the capability to act both on high and low density and the variations of this material, demonstrating no difficulties with differences in density of the material. One additional 2018 case investigated a CNC router cutting complex molds out of white plastic on another’s company 5-axis CNC.

Plasma Cutting Machines

A plasma cutting machine is an essential tool in the fabrication industry. These cutting machines can cut thick and tough metals swiftly and accurately. They use a plasma torch to heat metals to a molten state. Thus, this fast method of cutting allows cutting the materials that are hard or even impossible to cut by using other ways. The purpose of this paper is to identify and describe the core features, main functions, and examples of using plasma cutting machines.

Core Features and Functions

It is important to note that plasma cutters are famous for their quickness and accuracy. These machines can reach 45,000 degrees Fahrenheit in hot. Thus, a plasma cutting machine can cut the metal at the speed quicker than any type of traditional torch or any mechanical cutters. According to Haresh Khemani in 2022, a construction company cut the big steel beams with the CNC plasma cutting machine for the bridge. The company was surprised that it estimated half the time for cutting compared to the standard way of cutting.

Types of Plasma Cutting Machines

There are two main types of plasma cutting machines, manual and computer numerical control (CNC) cutting machines. Manual plasma cutters are portable tools for minor projects or the ones that require more detailed work. The other type includes automatic plasma cutters controlled by CNC that are suitable for bigger projects and industrial use. Moreover, in 2019, a metal art studio used a CNC plasma cutting machine to create an aluminum and bronze sculpture of a jumping boy. These modern techniques allowed to create a unique sculpture at a high pace with utmost precision.

Material Handling and Flexibility

Plasma cutting machines can process different types and thicknesses of metals, from as low as 0.5 mm to 80 mm. They are flexible in terms of adjusting the power output and speed of cutting. This ability is especially beneficial for the cases when it is required cutting a thin sheet of metal like in the automotive industry. At the same time, with few adjustments, the plasma cutting machines can efficiently cut thick plate metals used for the ships building. Kamzelski in 2021 mentions the example of cutting 50 mm steel plates by the shipyard, which considerably reduces the time for making a big vessel.

Technological Advancements

Modern plasma cutters can boast the enhanced level of precision, and efficient torch design. The other case of a technologically advanced device is a cutting path control system integrated into CNC machines that can eliminate the possibly high error rates. It is interesting that at the company from 2020, new machines and technology allowed reducing the amount of waste material by 30%.

Operational Expertise

Cutting metals with plasma requires certain settings, including an amperage that depends on the thickness and the type of a metal, the speed of cutting, and the gas pressure. Reducing the time for making the repair by optimizing the cutting process is crucial for an ordinary automotive repair facility. Alternatively, a fire in the garage could occur again sooner or later. An example of professional expertise is Timothy Bailey, a technician from the Bradigan’s Auto Center, who used his own settings duly selected for the plasma cutter and cut the damaged steel frame that fixed a car from the roads for a while.

Grinders

CNC grinders are essential in the manufacturing process, as they offer a high-precision to accomplish tooling and finishing using metals, plastics, or other materials. The industries that need extreme accuracy, as well as excellent surface finishes, use this equipment widely. The examples of such industries are automotive or aerospace.

Types of CNC Grinders

CNC Grinders exist in various types, and the most widespread of them are

-

Surface grinders – to get surfaces flat.

-

Cylindrical grinders – to process cylinders.

-

Centerless grinders – to process things that should be round quickly and efficiently.

Hands on: The example of the importance of cylindrical grinders can be found in the automotive industry. For instance, in the production of engines, camshafts, and crankshafts.

Advanced Features and Applications

Some of these machines’ features include robotic loading and wheel dressing. The case in point is that in 2018, a large tool manufacturer added a robotic loading machine to his CNC grinder. As the target was to process precision tools, the project was successful, and a lot of instruments were produced.

Material Versatility

Modern CNC grinders can process a variety of materials and juggle between them ingeniously. Whatever the material is, whether it is engineering ceramics, hardened steel, or soft aluminum, the CNC grinder can tune its purpose to reach the best results. The case in point is that a tech company in 2020 produced mostly aerospace grade titanium, which is not only tough but also has a high-melting point. For this purpose, the CNC grinder operated at corners up to 45º, which otherwise would need to be milled.

Technological Advancements

Recent technological advancements include artificial intelligence and the Internet of Things. This system has sensors to analyze wear and performance. Then it changes its settings accordingly, following them to ensure a good consistency. In 2019 at a Swiss watchmakers’ factory, the outdated CNC grinder was updated. Now it increased its tolerance by 30% and trash by 60%. All components are within the required limits.

Operational Techniques

To operate a CNC grinder properly, it is necessary to do the following:

-

choose a grinding wheel

-

adjust the speed

-

control the material

In 2021, one of the American machine shops managed by Symmetry Machining Services, passed AIM to prove their proficiency in handling the most high-precision CNC grinders. The company produced car acoustical shells, which exceed industry standards in surface finishing and the rest of the parameters.