CNC lasers precisely cut metals, plastics, wood, glass, and acrylic, widely used in automotive, furniture, and decorative industries

Metals

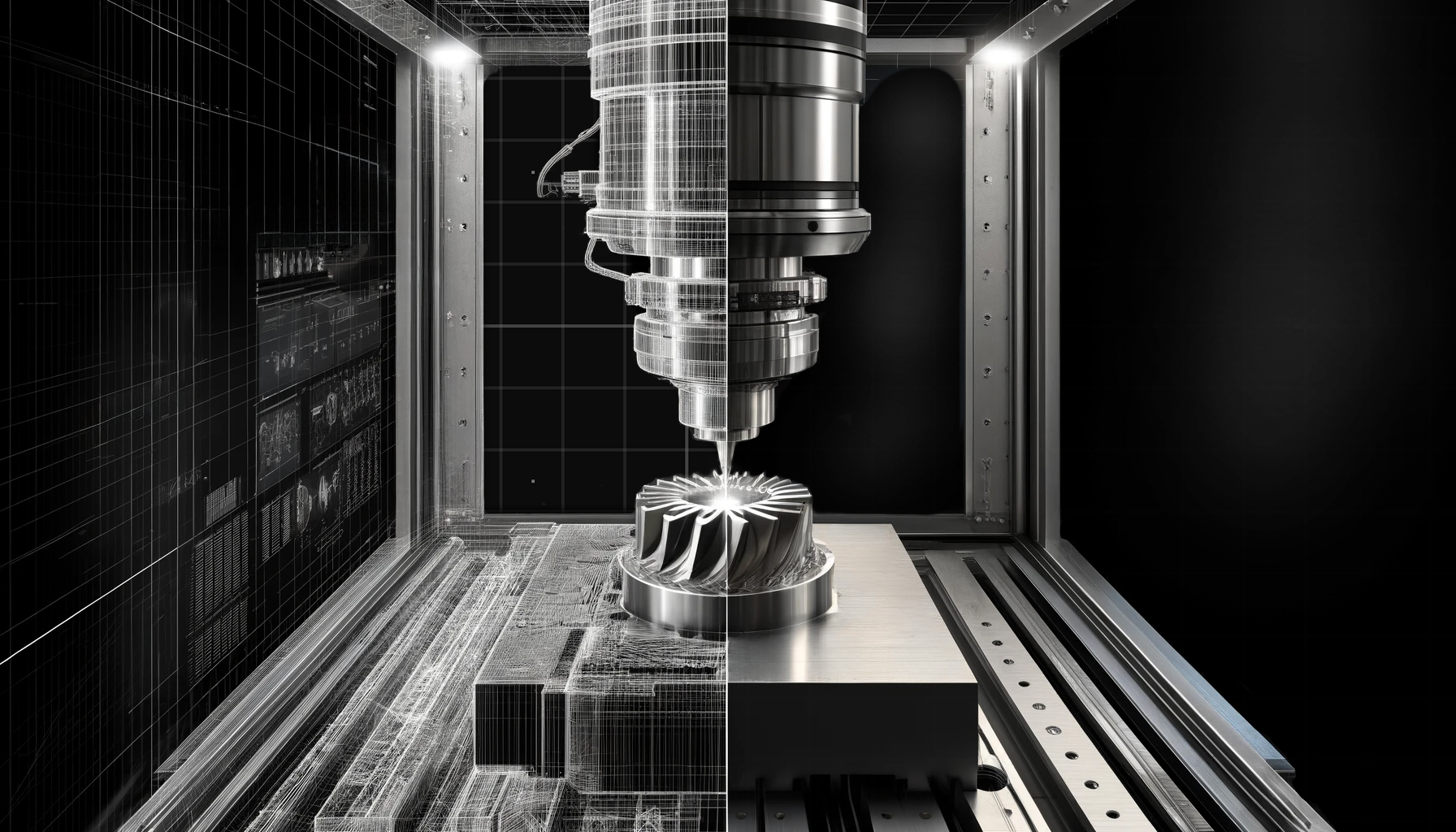

In industries like automotive, aerospace, and industrial machinery where precision and efficiency are everything, CNC laser cutting is the go to technology for that perfect cut.

Steel Cutting

Applications in industrial settings, such as construction or automotive, will use steel, due to its high strength and durability Varying Grades of Steelables CNthe CNcan processed byC laser, which includes Carbon steel, Stainless steel etc. As an instance, a 4 kW laser cutter machine is capable of slicing 10 mm thick carbon metallic at a velocity of 1.5 meters in line with a minute, with precision and best minimum heat-affected zone (HAZ). It is required specially to design complicated parts such as gears, or brackets that need to have perfect edge finish, and dimensionally accuracy.

Aluminum Applications

In the aerospace and automotive industries, where it is used because of its light weight and resistance to corrosion. Nevertheless, its extreme reflectiveness and its exceptional thermal conductivity make it challenging to laser cut. Fast cutting speeds of some 2 meters per minute can be attained by these specialized CNC lasers, with nitrogen as an assist gas, when cutting aluminum up to 6 mm thick. This increases the quality of the cut, gives less oxidation, and less burring which is vital for making aviation skins and automotive components.

Titanium Processing

Titanium is used in aero components and the medical community due to its excellent strength-to-weight favorability and oxidization resistance. To avoid titanium-turning-molten-wreck laser cutting requires tight control over material degradation, for which laser parameters are the most important. In case of five watt figure, a simple analogy that the laser beam can cut 0.5 mm thick paper and a ten-thousand watt figure can cut 300-400 mm thick titanium alloy. It is also essential due to the fact that these tolerance changes are important for the manufacture of intricate medical implants and high strength aerospace components that carry exacting business specifications.

Plastics

CNC laser cutting is an indispensable technology in the world of plastic fabrication, revered for yielding exact, sharp, and neat cuts, attributes that are crucial when producing intricate and precise components found across a broad range of sectors, most commonly the medical, automotive, and consumer electronics industries.

Acrylic Cutting

Because of its outstanding clarity, strength and aesthetics, acrylic is commonly used in retail displays and signage. CNC Laser: CNC Lasers can accurately cut, and typically use a 150-watt laser for up to 10 mm thick Acrylic Sheets. With this configuration, the laser can run at a speed of ~0.8 meters per minute and results in polish enough that we do not have to post improve the parts. The process is especially useful to produce complex shapes and letters in signage, where the smoothness of edges is required.

Polycarbonate Sheets

Some of these materials also offer superior impact resistance and optical properties and are used for protective covers and machine guards. Polycarbonate for example is one of the go-to plastics for its impact resistance and is used for everything from eyewear to riot gear. For example, a 100-watt laser can cut polycarbonate sheets that are up to 2 mm thick at speeds around 1.2 m/min. On the one hand, it is important to optimize laser settings so that the material can not overheat and color, and on the other hand, these settings set the quality of the WWBond production process. This precise tuning makes certain that the material remains both optically clear and structurally sound after being cut, which is essential for some important applications like safety glasses and industrial safety barriers.

PVC Processing

Although versatile and extremely common, PVC is also chemically unstable, and CNC lasers often produce chlorine gas when cutting it. Safer practices for cutting PVC involve turning down the power perhaps to only 50 watts and also slowing down the cutting speed to reduce the amount of toxic fumes. Moreover, a mount of gas phase is caught by trained ventilation systems. In doing so, this modification is absolutely necessary in order to fulfill safety requirements for the processing of PVC for applications like piping as well as wall claddings in construction.

Wood

CNC laser cutting is an excellent choice to cut wood as it offers complex designs, and great precision that are indispensable in sectors such as furniture, crafts, and construction.

Hardwood Cutting

Fine woodworkers typically use hardwoods such as oak, walnut, and maple for their durability (though many softer woods may be used) and typically build legs, backing and structural elements using these types of woods. A standard CNC laser system for this kind of job would be a laser with around 120 to 150 watts of power. Take 6 mm thick walnut as an example, it requires a setting that balances the speed and power to just avoid burning, usually set at about 0.6 meters per minute. This ensures smooth cuts and keeps the original high quality finish of the wood intact; allowing for equally high quality furniture and decorative objects to be crafted.

Softwood Applications

Softwoods, like pine and cedar, are less dense so they cut much faster using a laser. Entered around coarser, rather less detail-oriented subjects, for example, compositional scale in addition to simple furnishings pieces. A 100 watt laser will cut 10mm pine kerf free at about 1.2 meters per minute. Its faster speed makes it ideal for mass production circumstances while maintaining the precision required for fit and assembly.

Plywood Processing

Wooden plywood is also one of the versatile materials that are being used for multiple applications from interior designing to the construction templates. Indeed, the flexibility to cut elaborate patterns out of even thicker 4 to 12 mm ply is what the extra precision afforded by a CNC laser can provide; or simply to bulk-prepare several layers of ply using the higher cutting speed to generate for instance multiples of the same joinery detail. For Detailed CutsOrnate inlays and custom furniture overlays8mm Plywood0.8 meter / minute (max speed) 8mm PlywoodRequires 130 watts laser beam Control over the laser settings means less kerf and have smooth edges – which are vital for high quality finish in any design project.

Glass

A method of cutting glass that achieves the precision of cutting marble and reduces the breakage to a minimum, in particular, that may be employed in the architectural, automotive and artistic industry.

Architectural Glass Cutting

In architecture one of the most common applications is the cutting of glass, usually to create exact dimensions for windows, facades, internal partitions and soles of large dimensions. As an example, near 400 watts CO2 laser can be fine-tuned to cut 10 mm of tempered glass. Usually the process runs at a speed of 0.2 meters per minute to cut cleanly and not heat to the point of randomly cracking or weakening the glass.

Automotive Glass Applications

CNC lasers are also used for high-quality cutting of auto windshields and windows (drill free). The automotive sector CNC carbon dioxide laser, of course, is a development of the tube laser type. It has been specifically tuned for laser parameters and works at speeds on the order of those that will protect automotive 6 mm glass while allowing for the accurate cuts required for exact fitting.

Artistic Glass Design

Glass artists often rely on CNC laser cutting cutting to carve detailed designs on glass, such as scratches or laminated designs. Laser cutting makes it possible to do fine work such as cutting shapes in 4 mm thick glass at a speed of around 0.5 meters per minute. This method is useful for art installations where each cut will define the character of the work .

Acrylic

Acrylic is one commonly used material that is well-loved for its aesthetic transparency, durability, and flexibility, and CNC laser cutting is highly prevalent in its processing. It is widely used in the advertising, art as well as the retail industry because it is a functional and eye-catching material.

Commercial Signage

The major appeal with acrylic in commercial signage is that it has a similar high-gloss finish as glass but without the fragile nature. Thick acrylics, usually in the 20-millimeter range, require relatively burly, high-power lasers – 150 to 200 watts. This results in extremely fast cutting speeds, typically 1 meter per minute, depending on the exact thickness and quality needed. Flame polishing using this process yields edge quality equal to that of solvent welded edges, which is much smoother and more attractive than the “sawn” look of laser-cut edges with no further processing. The most important factor for signs that are going to be used outdoors and need both visibility and signs that read bright.

Retail Displays

Retail displays often demand angles and the shapes have produce in an intricate or accurate cut format. It requires a 100-watt laser to cut medium thick (8 mm) acrylic, however, almost at the speed of 0. You can make more elaborate designs with this setup, great for intricate logos, branded display racks, or custom shelves that you want to be both strong and clean and modern-looking. CNC lasers can cut intricate shapes to create a custom fit to make your store one-of-a-kind in its arrangement and display of themes.

Artistic Applications

While in artwork, acrylics adds light to the painting, thus creating a sense of, 3D and more interesting. CNC laser cutting – used by artists; produces accurate point of expensive (artists do CNC on 3-5 mm thickness acrylic glass). However, as intricate designs and acrylic are particularly sensitive to heat, the cutting process must be carefully managed at lower speeds so as to not compromise the details of the design or cause damage to of the Acrylic due to high temperatures reached during the cutting process. Options like these are critical for certain artworks that depend on intricate patterns, layered constructions, or engravings that propel the work’s story or aesthetics.

Prototyping and Model Making

Acrylic is also widely accepted within prototyping and model making. Since its very easy to work with Styrofoam it is also ideal for crafting prototypes and architectural models due to its high dimensional stability. Laser cutting is highly accurate to within very tight tolerances, which is vital for parts that need to fit together perfectly. One of the most exact machine-oriented uses of CNC laser technology is in engineering and architectural designs, where prototypes have to match their end products or structures.