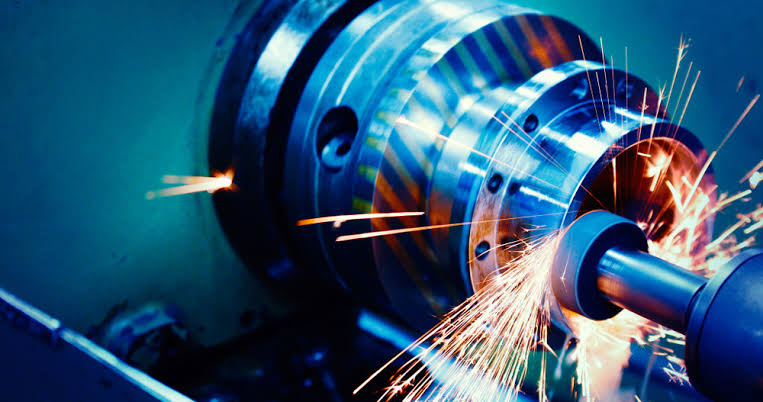

How Much Does It Cost To Operate A CNC Machine Tool Every Day

The daily cost of operating a CNC machine involves several factors, including electricity consumption, maintenance, and tool wear. These costs are influenced by the type and frequency of machine use and can be reduced through energy-efficient practices and regular maintenance. Basic Components Of Operating Costs Power Consumption Electricity expenditure is a large proportion of operating …

How Much Does It Cost To Operate A CNC Machine Tool Every Day Read More »