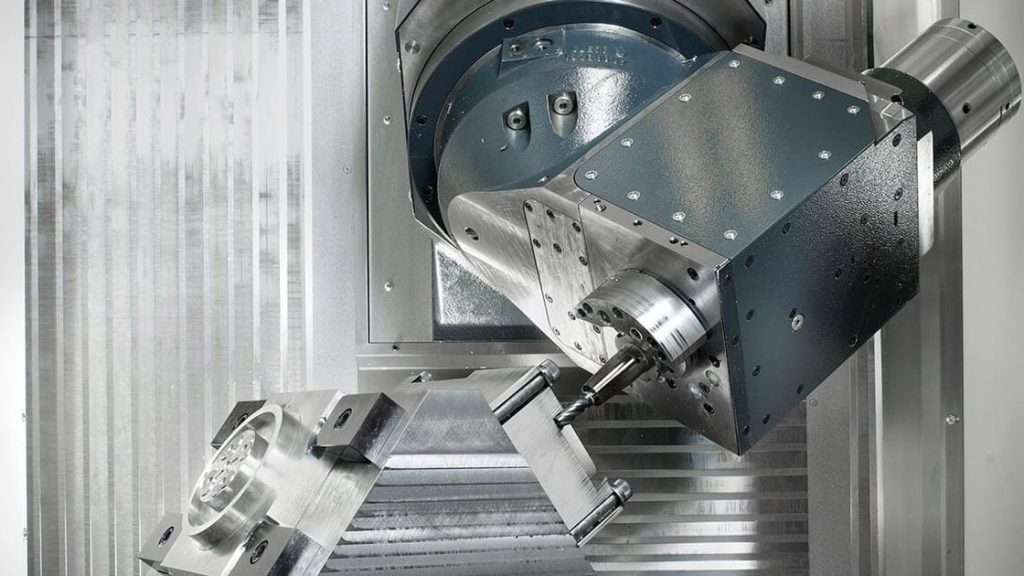

What is 5-axis CNC machining

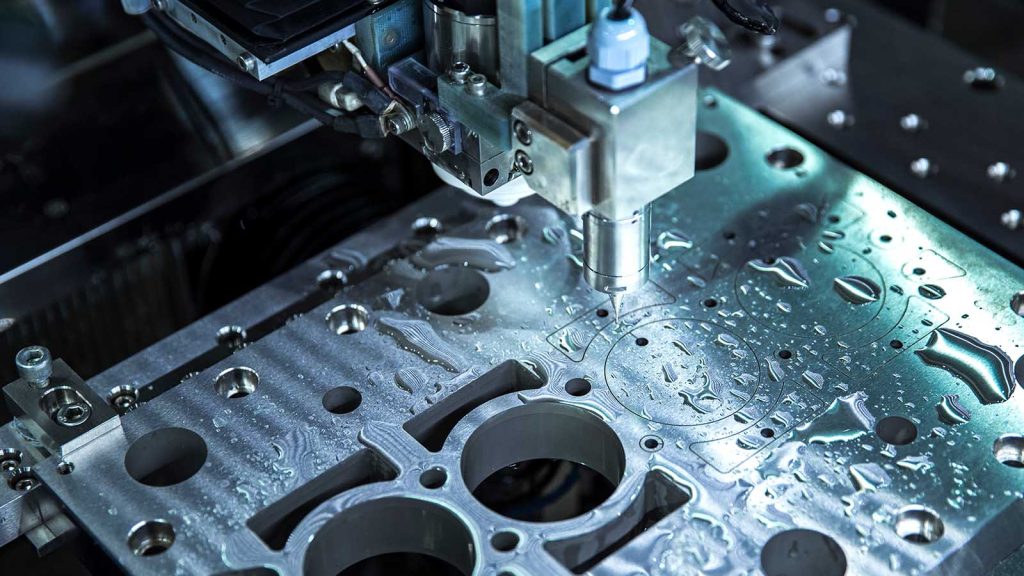

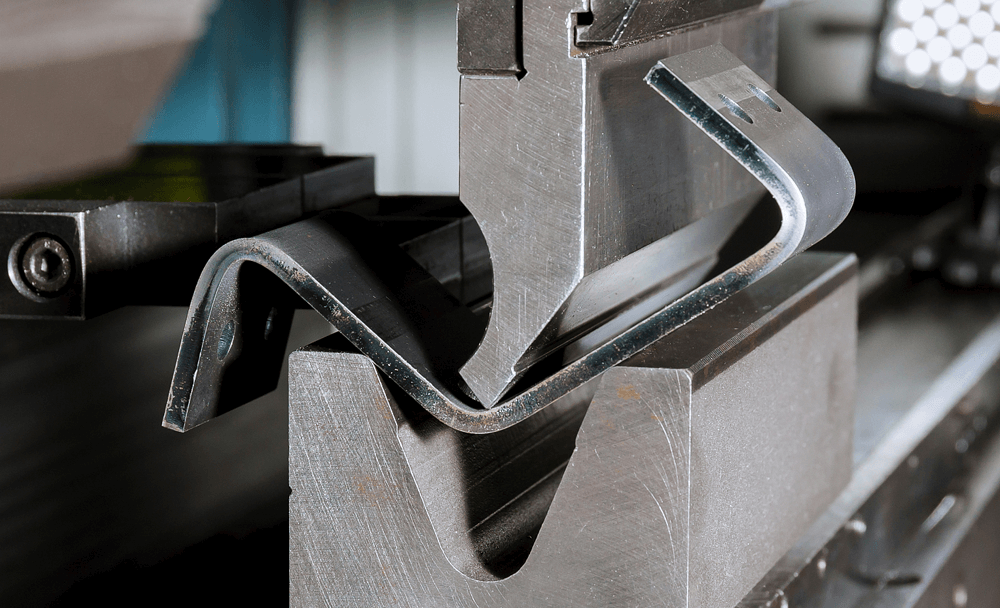

Five-axis CNC machining is a high-precision technology that simultaneously operates on X, Y, and Z linear axes and A and B rotational axes, allowing for detailed processing of complex parts. For example, it can achieve aerospace component machining with precision up to 0.001 mm in a single setup. Technical Principles of Five-Axis CNC Machines The …