What is the difference between 3 axis and 4 axis CNC machine

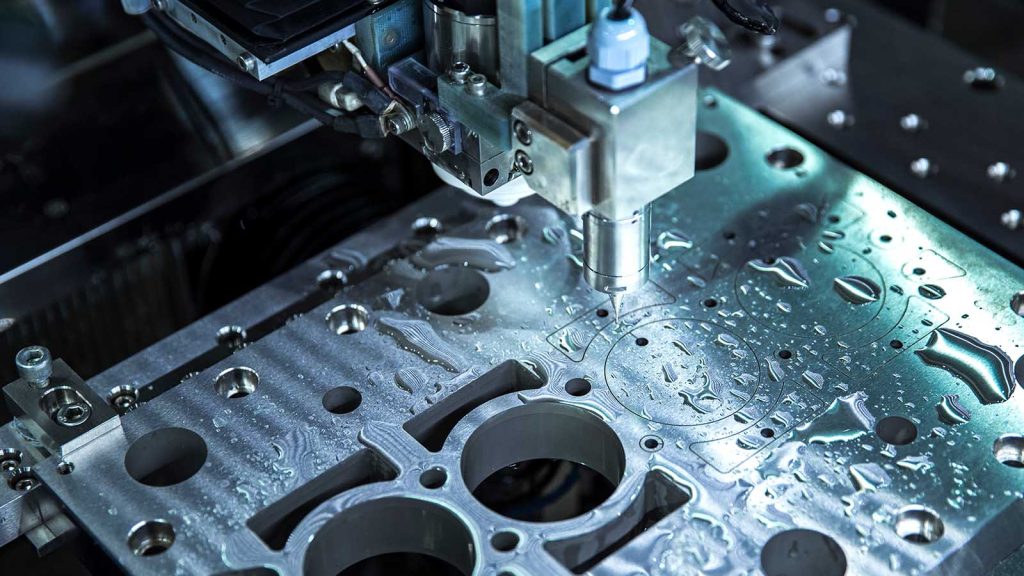

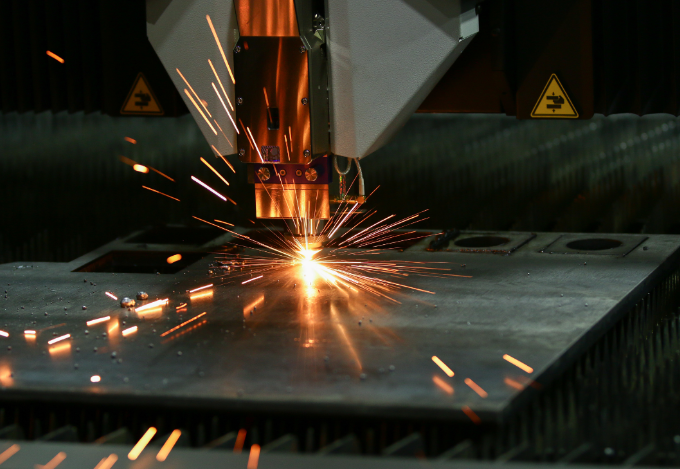

A 3-axis CNC machine is ideal for basic 2D and simple 3D machining, with an accuracy of ±0.01mm and costs around $50,000 to $100,000. A 4-axis CNC machine adds the A-axis for complex parts, achieving ±0.005mm accuracy, and costs around $100,000 to $200,000. Characteristics of 3-Axis CNC Machines It is just amazing to see the …

What is the difference between 3 axis and 4 axis CNC machine Read More »