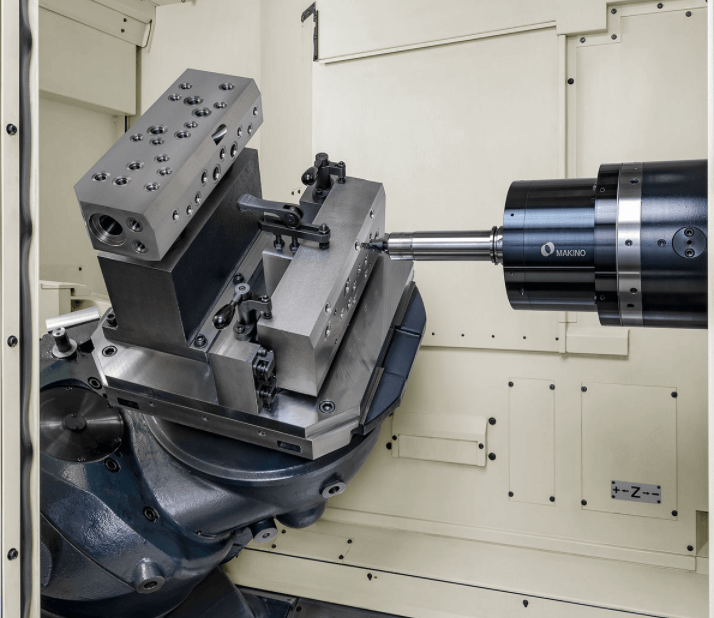

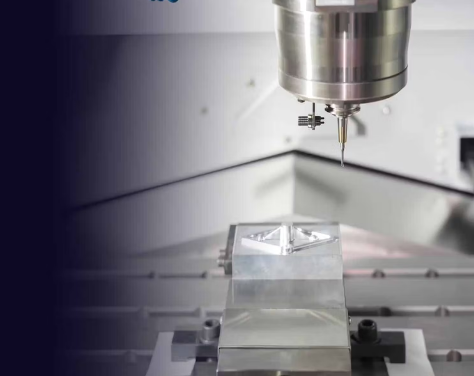

7 ways CNC is better than lathes

CNC machines outperform lathes in precision, achieving tolerances as tight as 0.0005 inches, enable 24/7 automated operations, reduce material waste, and streamline complex designs with ease via advanced programming. Precision and Accuracy One of the most essential aspects for which CNC machines are notably better in the domain of manufacturing is their extraordinary precision and …