5 Eco-Friendly Practices In CNC Machining

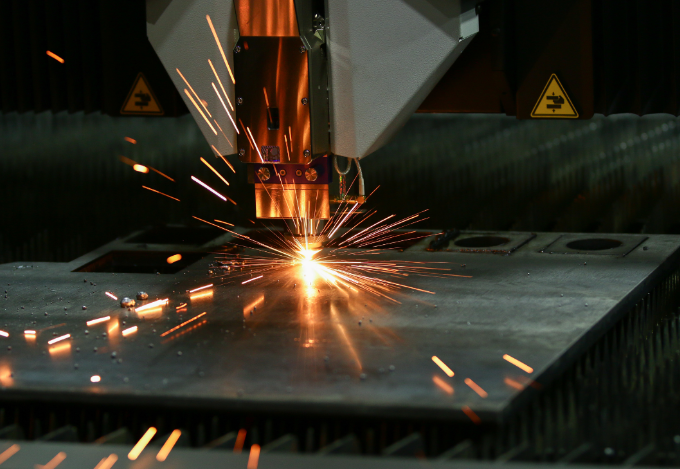

In CNC machining, five eco-friendly practices are material optimization, energy efficiency, recycling and reuse, integration of renewable energy, and the use of advanced technologies. Material Optimization Material optimization in CNC machiningOne of the most compelling reasons for optimizing the material used in the CNC machining is to reduce waste and increasing the cost effectiveness. At …