5 Steps To Optimize CNC Machining

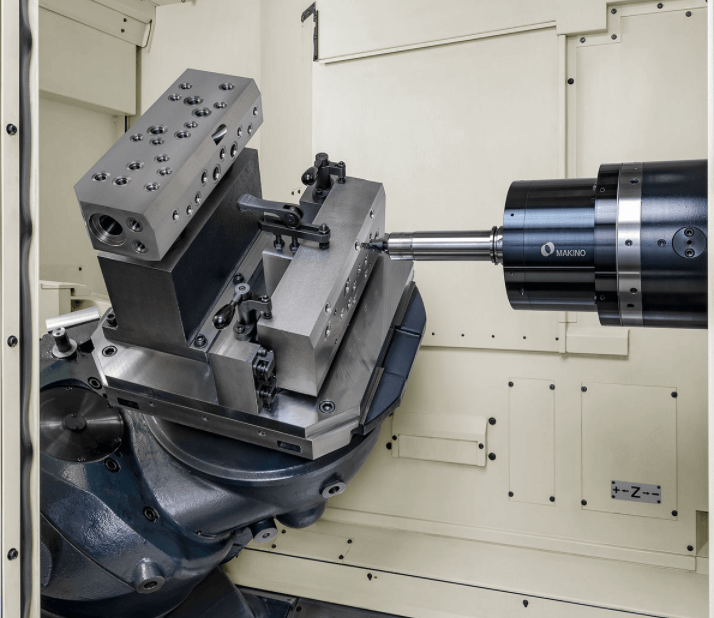

Implement predictive maintenance to reduce downtime, upgrade tooling for faster production, optimize cutting parameters with AI, enhance machine calibration for accuracy, and adopt lean manufacturing to boost efficiency Setup Efficiency MACHINE AND TOOL PRESETTING & MANAGEMENT The road to greater setup efficiency actually starts with the use of intelligent tool presetting. Manufacturers are also reducing …