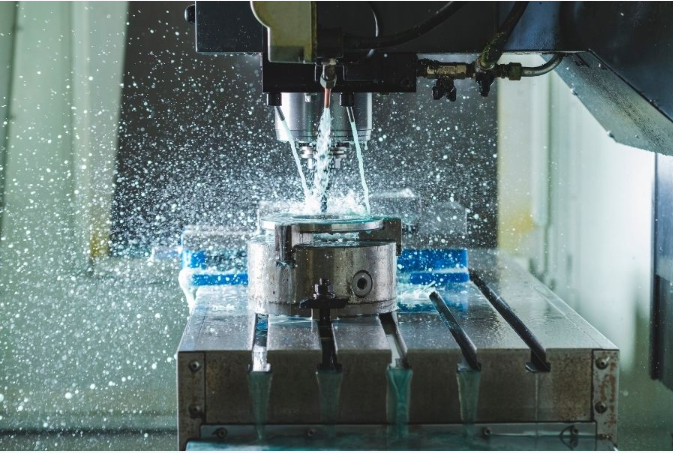

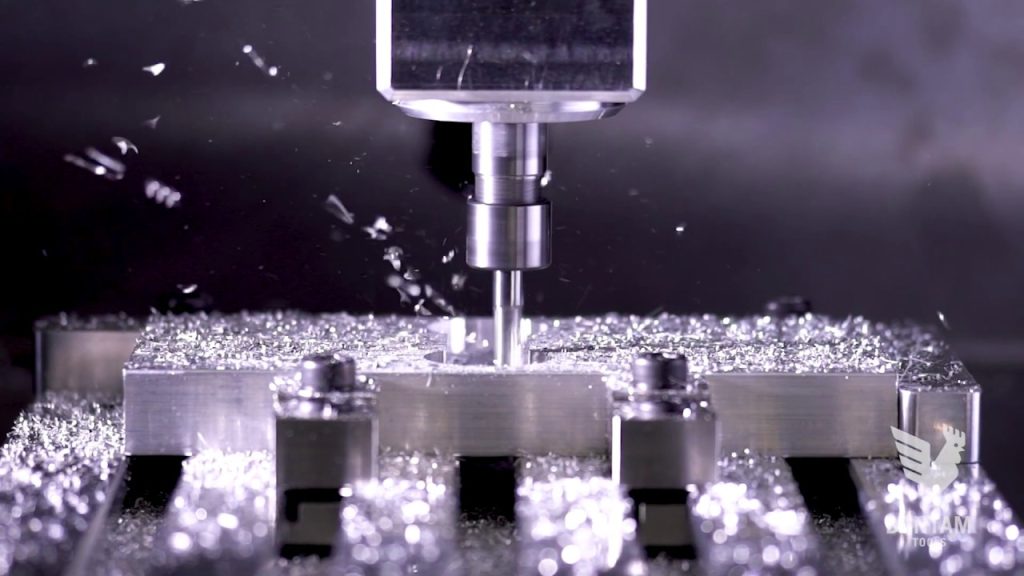

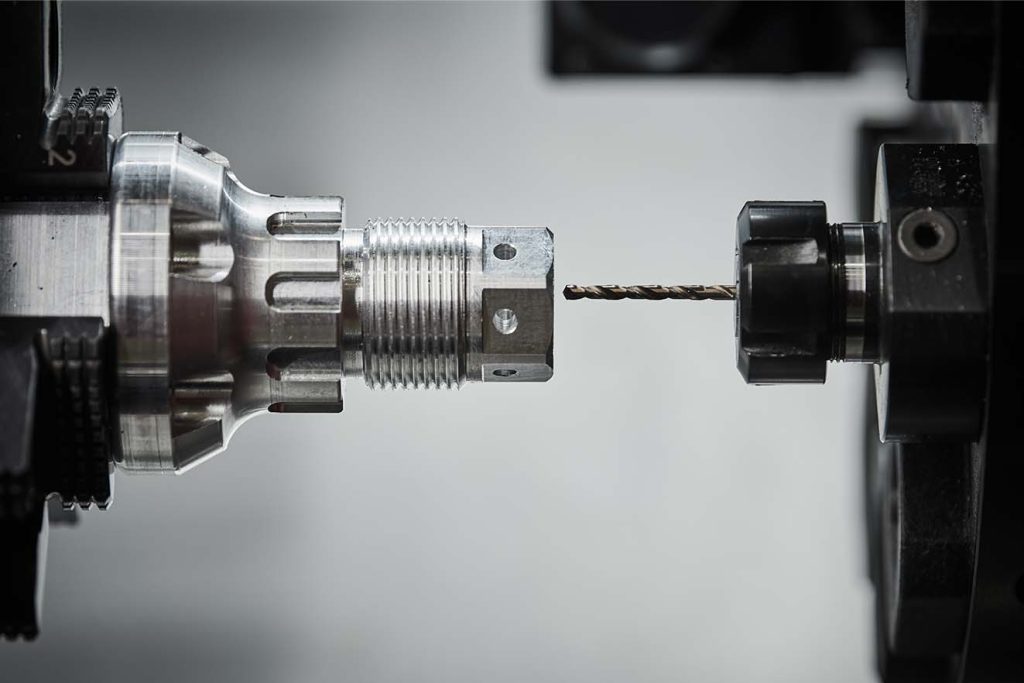

5 Ways CNC Boosts Metal Precision

CNC enhances metal precision through automated controls, achieving tighter tolerances, and reducing human error. This method allows for consistency in high-volume production, ensuring parts meet exact specifications CNC in Metal Fabrication CNC technology has made a primary contribution to changing metal fabrication and making it more precise. It implies using a computer to convert a …