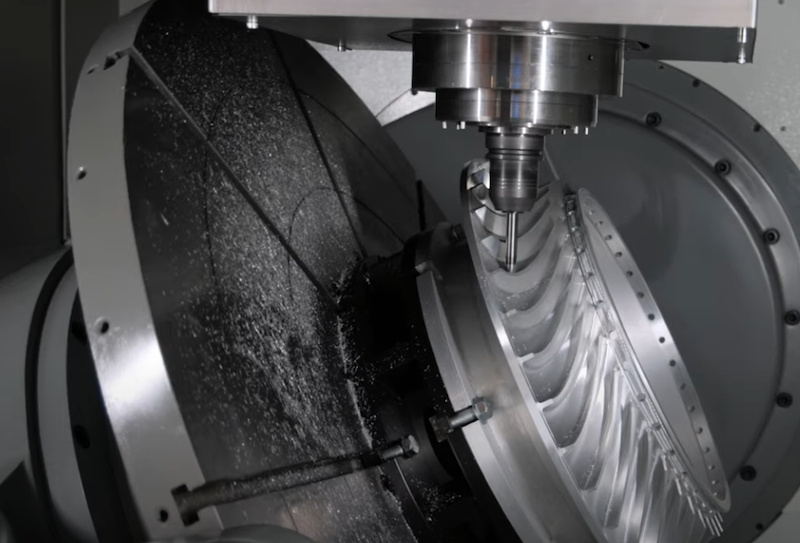

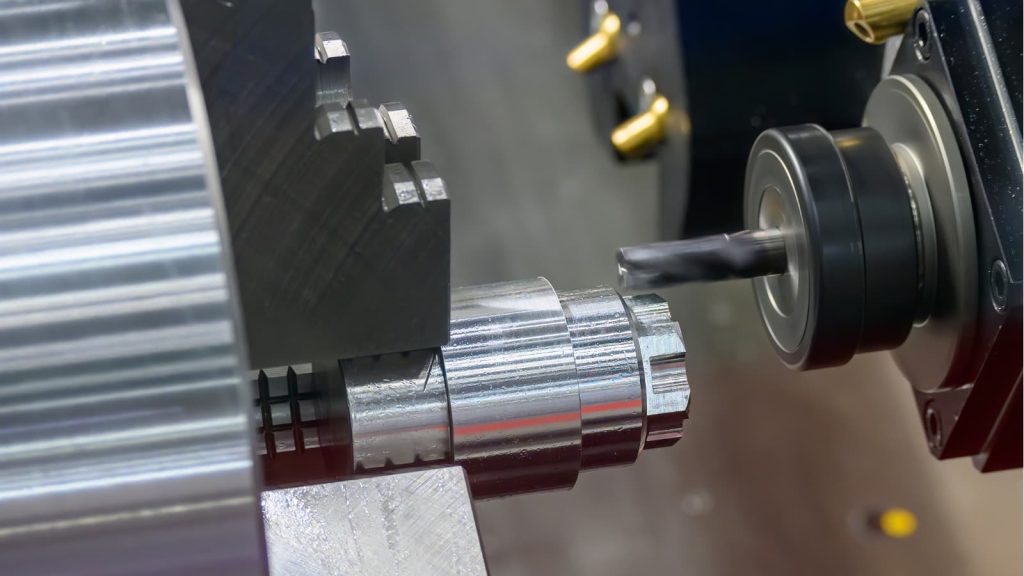

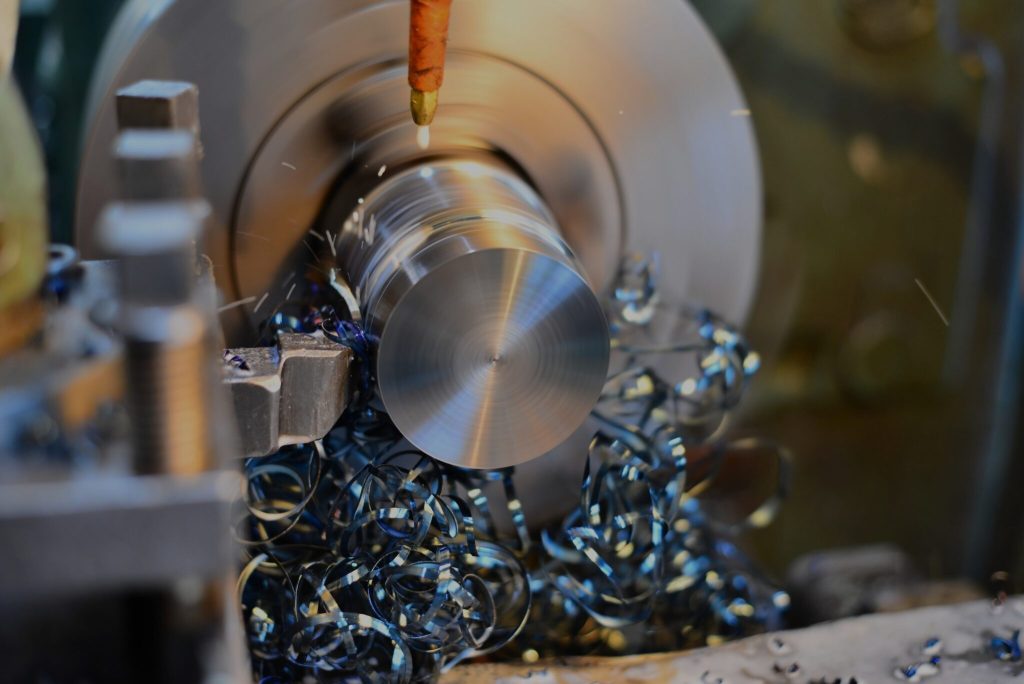

6 Durable CNC Machined Materials

There are 6 durable CNC machined materials: stainless steel, titanium, alloy steel, carbon steel, aluminum, brass Stainless Steel Stainless steel is one of the top materials for CNC machining, lauded for its immense durability and corrosion resistance. It is a widely used material, employed in the majority of industries, from aerospace and automotive to medical …