5 Industries Changed By CNC Milling Technology

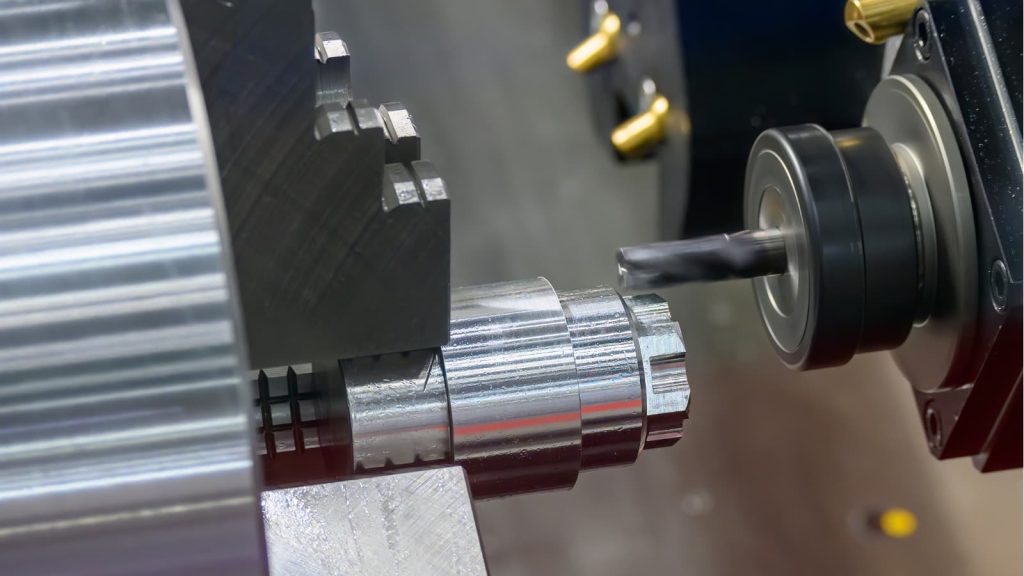

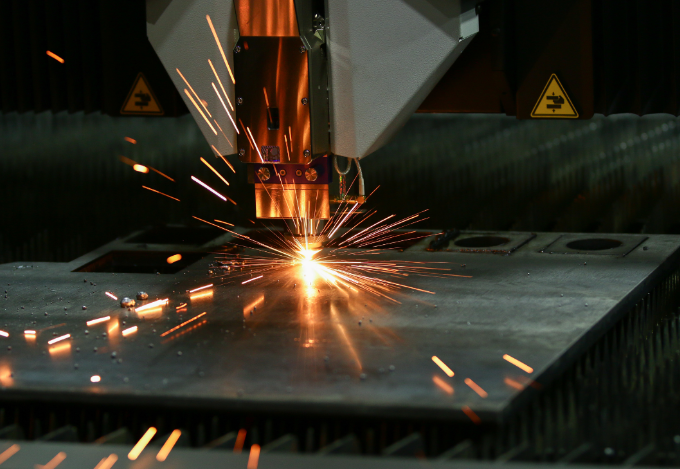

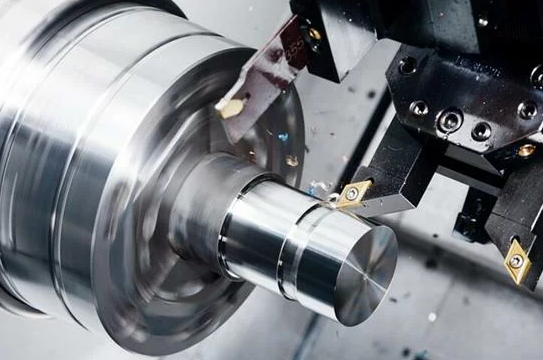

CNC milling has revolutionized aerospace, automotive, medical, electronics, and manufacturing industries by enhancing precision, efficiency, and allowing for complex, customized component production Aerospace CNC milling has reshaped how the aerospace industry operates, increasing the accuracy and speed of manufacturing processes that are all-important for both commercial and military aircraft. The ability of CNC milling technology …