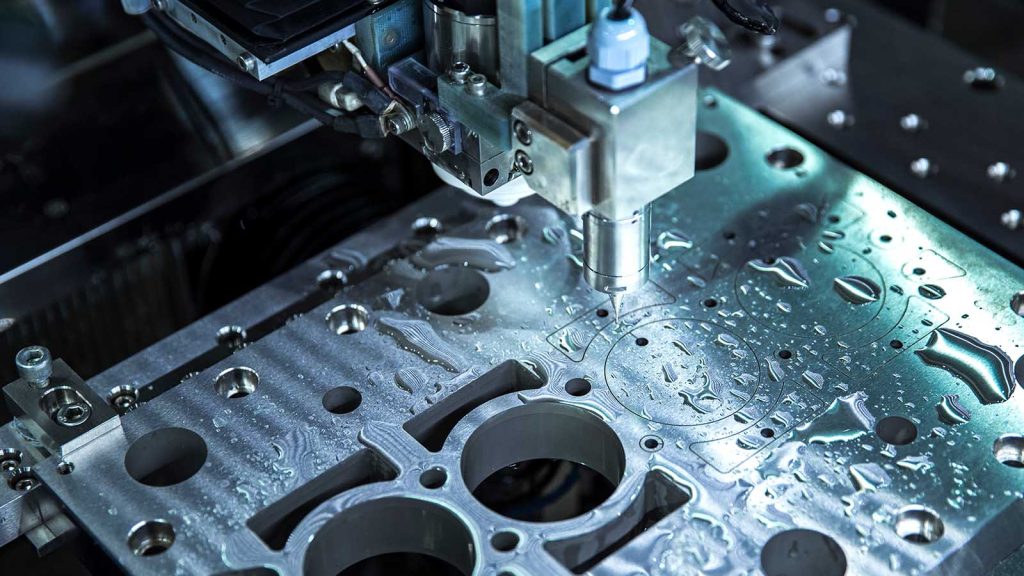

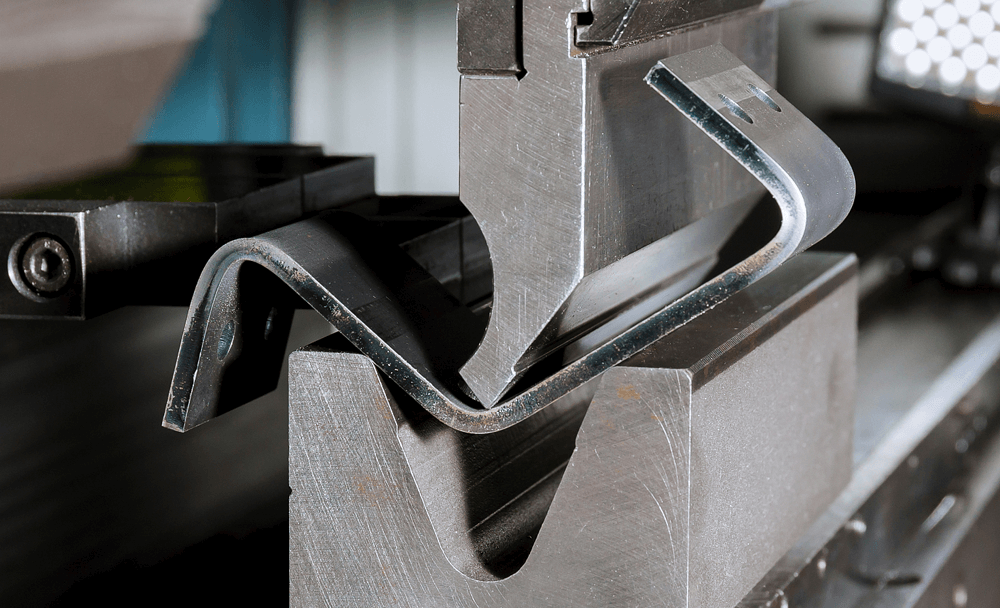

How to optimize the design and manufacture of medical devices with CNC machining

By using CNC machining technology, the design and manufacture of medical devices can achieve precision up to 0.01 mm, reduce design time by 30%, and lower costs by 15%-20%. Optimizing cutting speed and feed rate can improve production efficiency by 15%-25%. Choosing the Right Materials and Tools The main materials are stainless steel, titanium alloy …

How to optimize the design and manufacture of medical devices with CNC machining Read More »