5 Essential Tools For CNC Machining

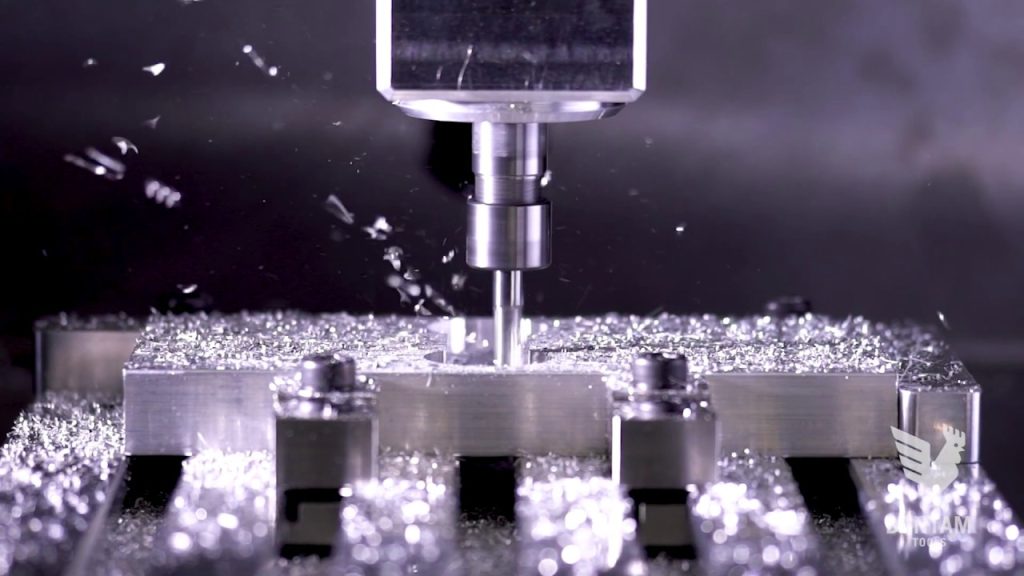

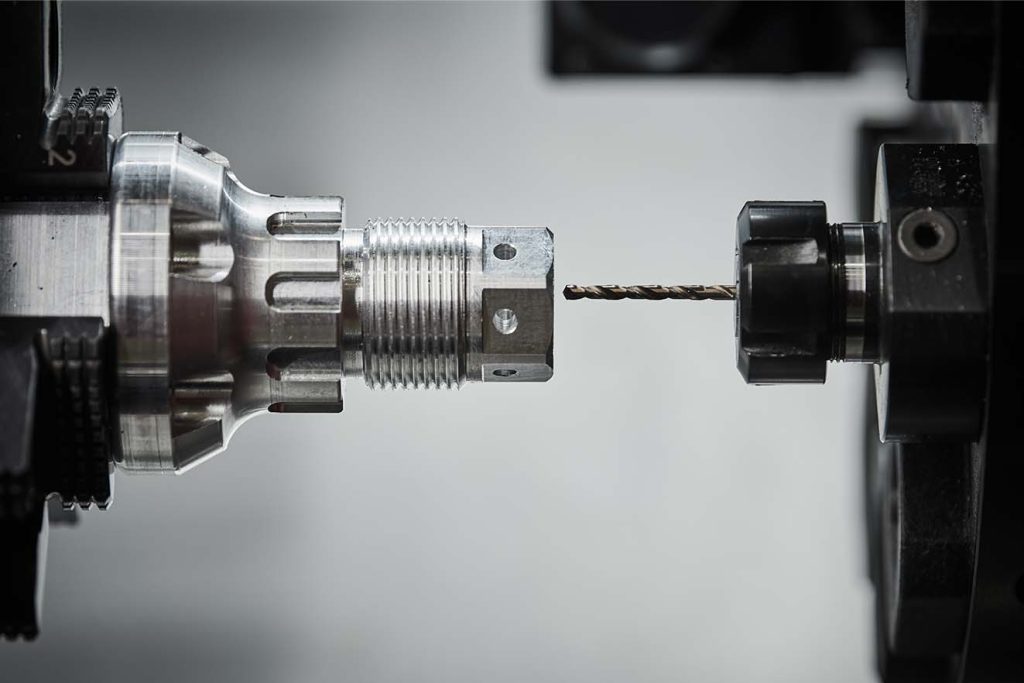

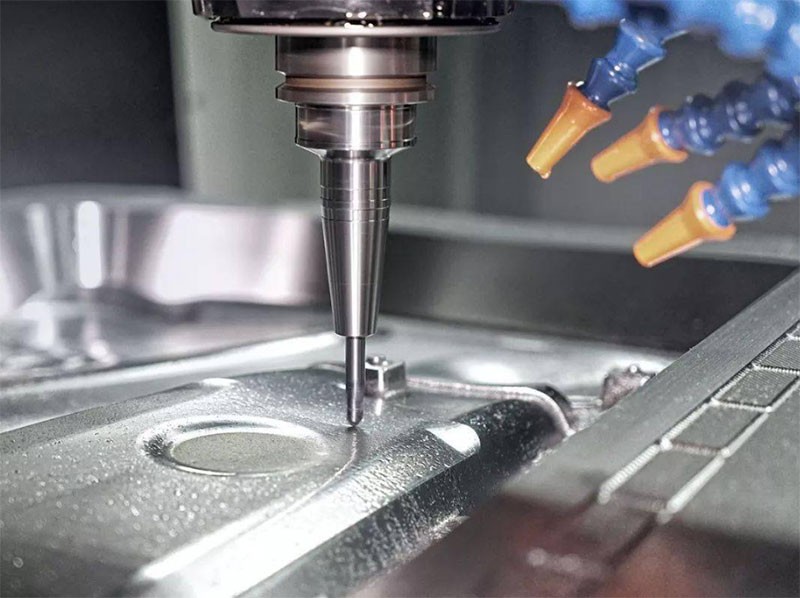

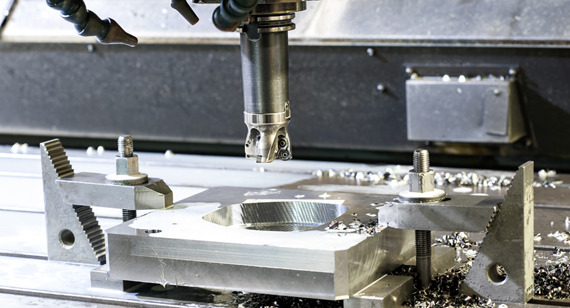

Essential tools: high-speed steel end mills, lathe tools, workholding devices, calipers, coolant systems. Ensure precision, reduce heat, improve CNC machining efficiency CNC milling cutter Selection The selection of the CNC milling cutters in the key to efficient machining. Important factors include material, coating and geometry. High-speed steel and carbide cutters are the most widely used …