5 Differences Between CNC And Laser Cutting

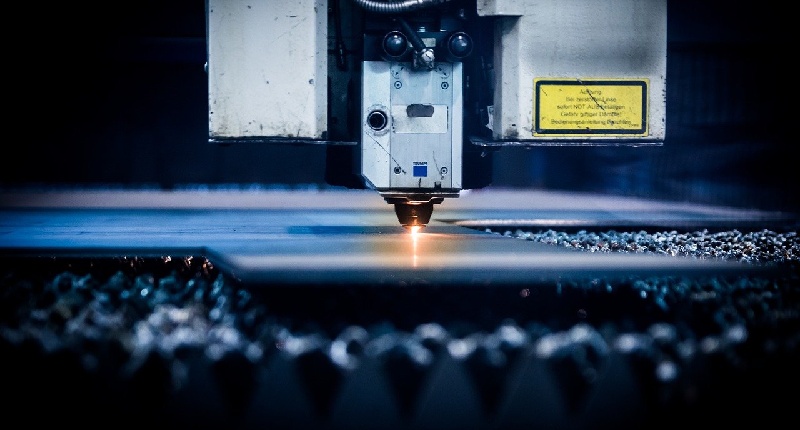

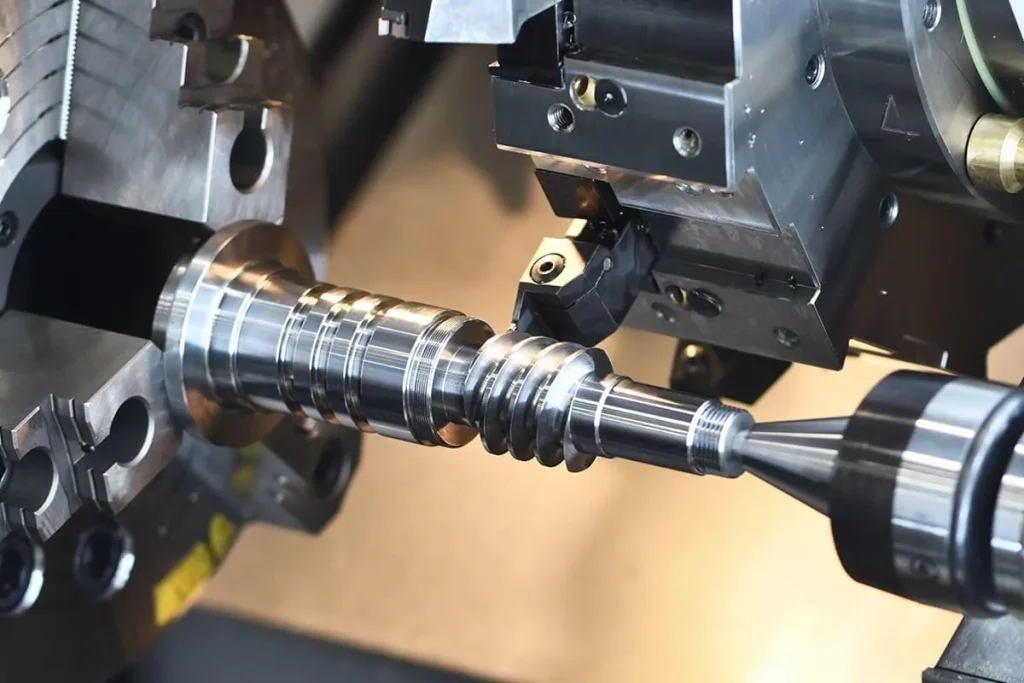

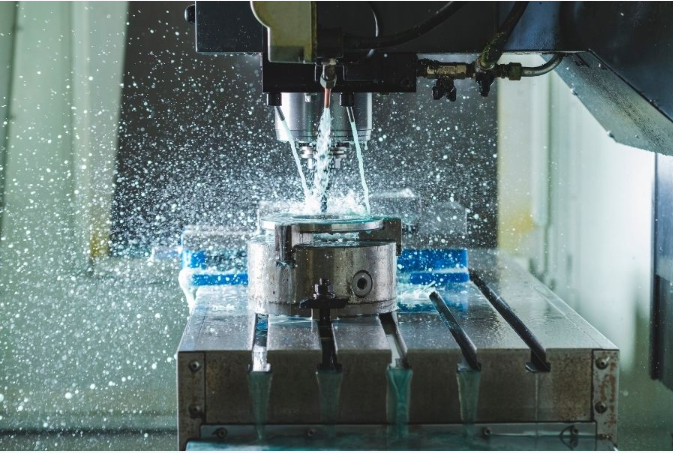

CNC cutting uses physical contact and tools, favoring larger, simpler designs; laser cutting employs a high-precision beam, excelling in intricate patterns and clean edges. Laser is more expensive but offers unmatched detail and efficiency CNC and Laser CNC and laser cutting are two important technologies in manufacturing employed to precision-cut a variety of materials. Specifically, …