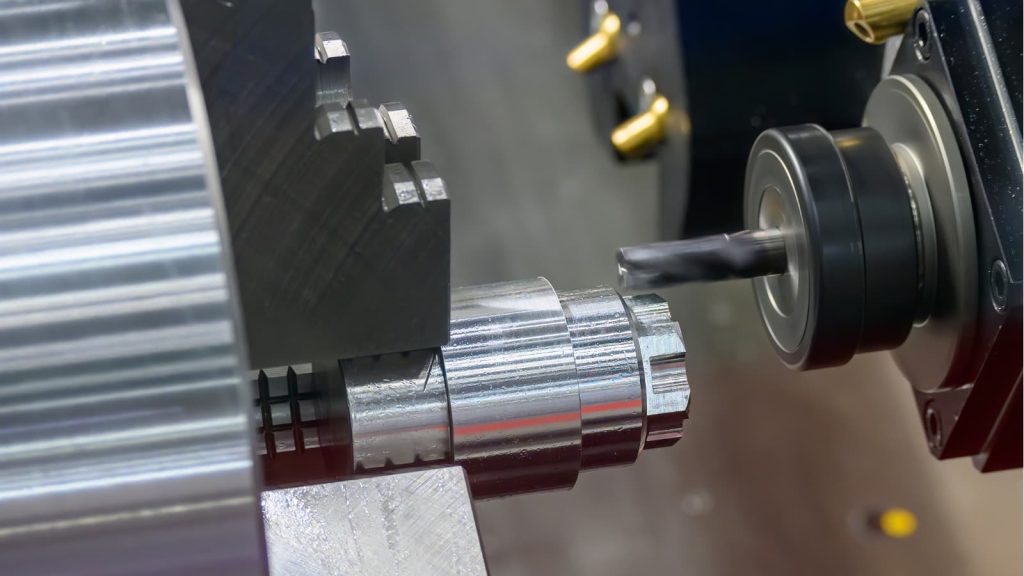

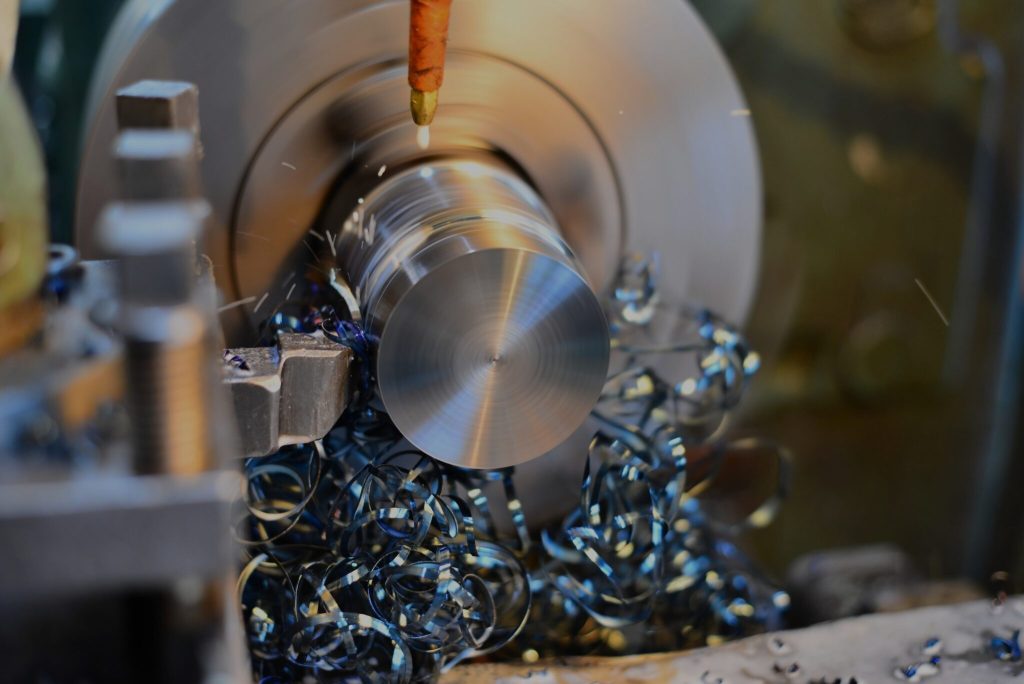

5 Types Of CNC Cutting Tools And Their Uses

High-speed steel for versatility, carbide for tough materials, ceramic for heat resistance, diamond for superior finishes, and specialized tools for unique tasks High-Speed Steel Tools High-Speed Steel tools are a staple of CNC machining in general, offering a mixture of toughness and high-temperature softening resistance. This type of steel normally consists of carbon steel alloyed …