6 main differences between manual machining and CNC machining

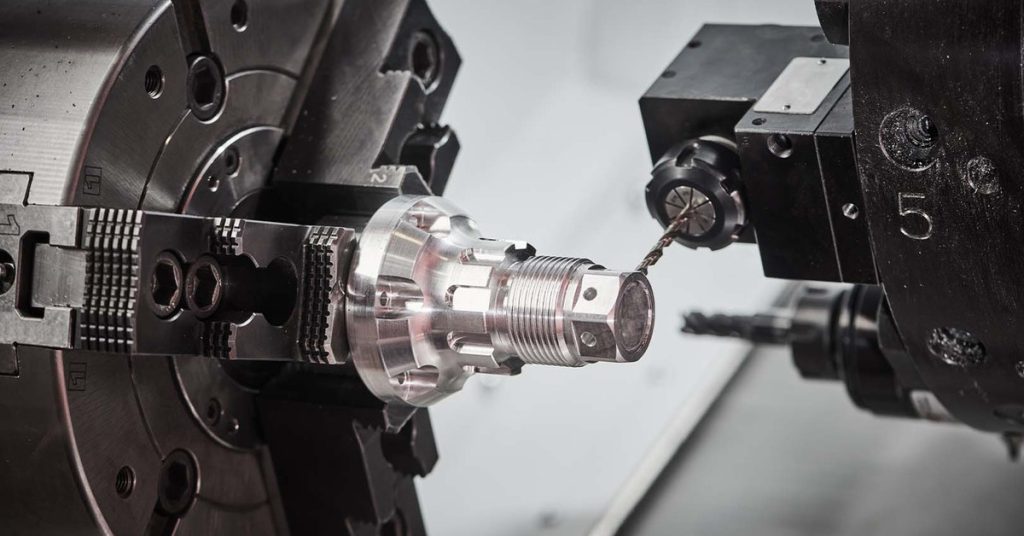

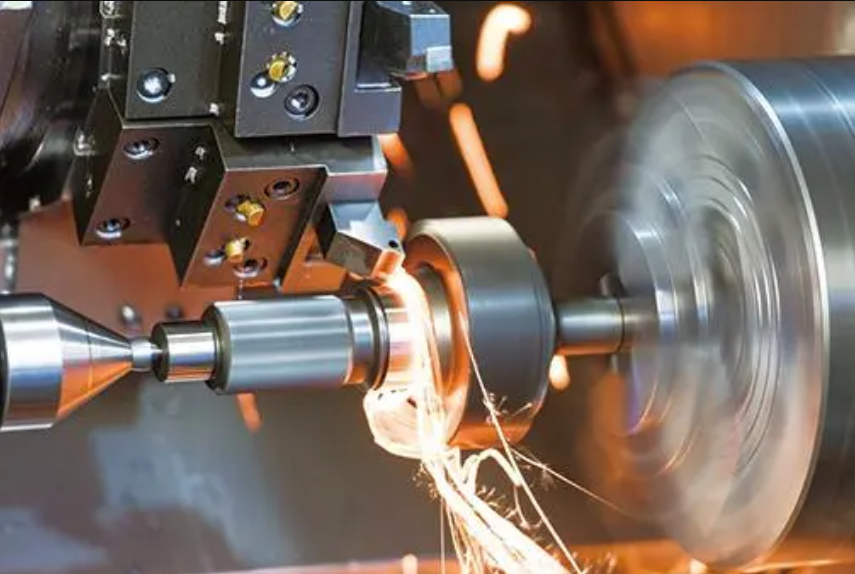

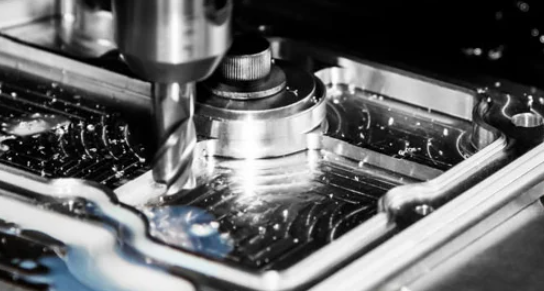

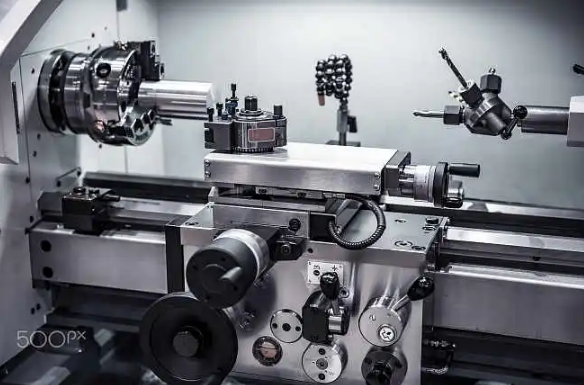

Manual machining requires direct control and skill, suitable for unique, low-volume tasks. CNC machining uses computer programs for precise, high-volume production, reaching tolerances up to ±0.0001 inches, reducing errors and material waste. Control Method Manual machining is, naturally, carried out manually by the operator physically turning cranks, handwheels, levers, and adjusting various devices using hand …

6 main differences between manual machining and CNC machining Read More »