Aluminum Die Casting Services

- Precision

- Strength

- Versatility

Why Choose RS MFG for Die Casting

Specializes in die casting using advanced machinery and expert knowledge of aluminum alloys, ensuring precise, high-quality parts across all production volumes with strict quality control.

Quality Assurance

Strict quality control measures to ensure excellence in every cast.

Finishing Services

Comprehensive finishing options to meet aesthetic and functional requirements.

Volume Flexibility

Capacity for both low and high-volume production runs.

High Precision

Commitment to delivering parts with exceptional accuracy and detail.

Material Expertise

Knowledge of various aluminum alloys to meet specific application needs.

Advanced Technology

Cutting-edge die casting machinery for precise outcomes.

Our Die Casting Process

Design and Engineering

We collaborate with clients, utilizing CAD software for precise 3D modeling and prototyping.

Mold Design and Fabrication

We use advanced CNC machines to create precision-engineered molds, ensuring durability and accuracy.

Melting and Alloying

We select high-grade aluminum alloys and melt them, alloying to achieve optimal material properties.

Casting

We inject molten aluminum into molds at high pressure, crafting complex shapes with high dimensional accuracy.

Trimming and Deburring

We conduct post-casting processes to eliminate excess material and ensure smooth edges.

Heat Treatment

We improve mechanical properties through various heat treatment processes, enhancing durability.

Surface Finishing

We offer a range of finishing options like sand blasting, painting, and anodizing to boost aesthetics and performance.

Quality Control

We enforce rigorous inspection protocols at multiple stages to ensure industry standards are met.

Assembly and Packaging

We provide optional assembly services and custom packaging solutions, tailored to client needs.

Ready to Get a Aluminum Die Casting Quote?

Share the specifics of your project with us, and let’s join forces to bring your concepts to life. We guarantee a swift and professional response, ensuring your ideas are molded with precision and quality.

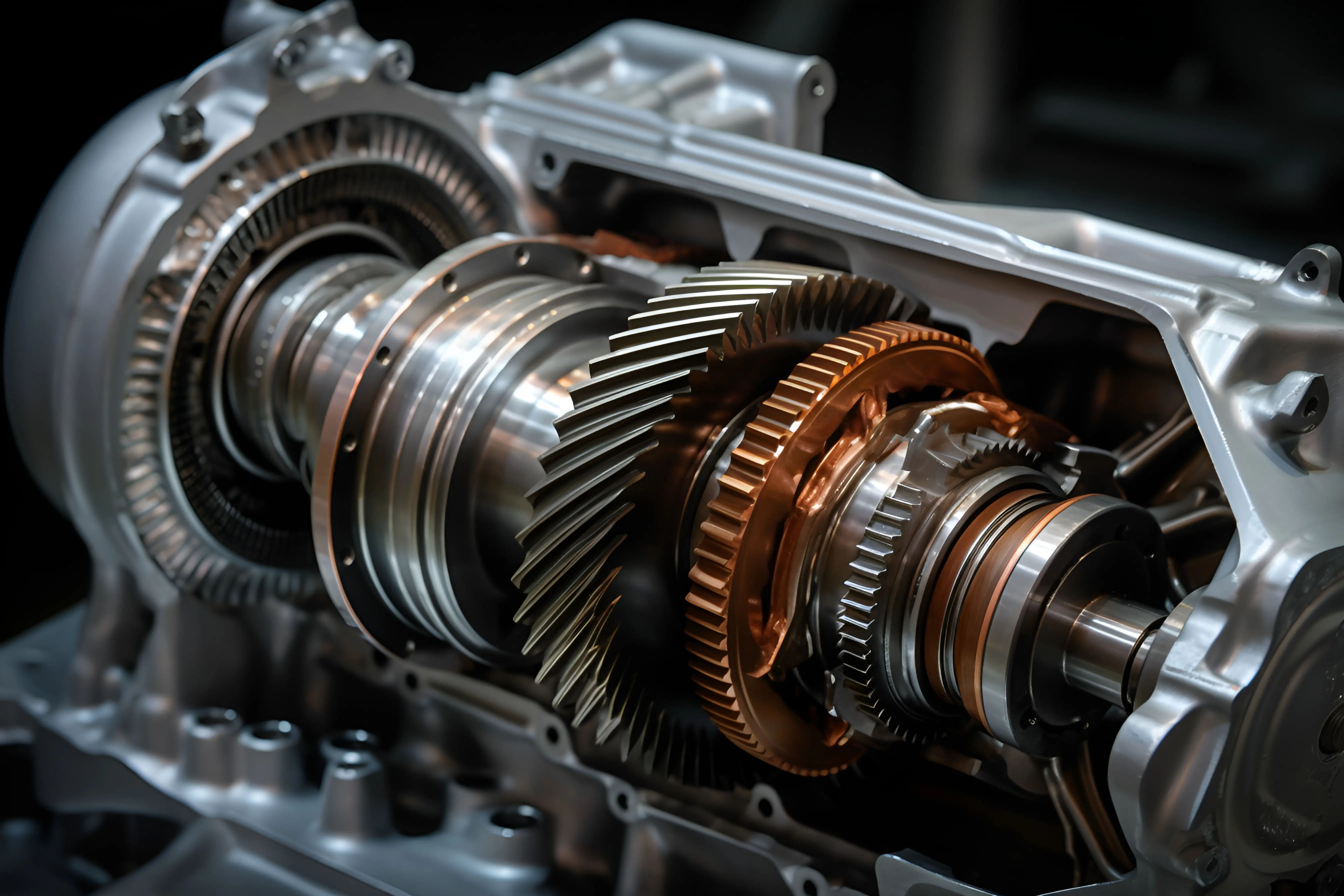

Industries We Serve & Case Study

Collaborated with a top automotive manufacturer to create lightweight, robust aluminum components for new electric vehicles using high-pressure die casting, ensuring they meet stringent industry standards.

- Achieving optimal lightweight strength.

- Ensuring high-precision component integrity.

- Adhering to strict production timelines.

Frequently Asked Questions (FAQ)

Answer:

Aluminum die casting is a metal casting process that involves forcing molten aluminum under high pressure into a mold cavity. This process is known for producing geometrically complex metal parts that are durable, dimensionally stable, and have good mechanical properties.

Answer:

We utilize a variety of aluminum alloys depending on the project requirements, including but not limited to A380, A383, A360, and K-Alloy. Each alloy offers different benefits, such as high strength, corrosion resistance, or excellent thermal properties.

Answer:

Yes, our facility is equipped with high-pressure die casting machines that can manufacture both small and large aluminum parts, meeting a wide range of size and weight specifications.

Answer:

Quality assurance is integral to our process. We perform dimensional checks, material testing, and structural inspections using advanced equipment like CMMs and X-ray machines. Our quality control measures ensure that each part meets the required tolerances and performance criteria.

Answer:

The lead time for die casting projects varies based on the complexity of the part, the quantity required, and the finishing processes involved. We work closely with clients to establish a timeline that meets their production schedule, typically ranging from a few weeks to several months for larger orders.

Answer:

Absolutely. We offer a complete suite of finishing services, including trimming, deburring, shot blasting, sanding, painting, powder coating, and anodizing to enhance the appearance and performance of the finished parts.

Answer:

Yes, our engineering team can assist with the design and prototyping of your parts. We use advanced CAD software to create detailed designs and simulations to ensure manufacturability and functionality before production begins.

Answer:

Our aluminum die casting services cater to a diverse range of industries, including automotive, aerospace, electronics, healthcare, and consumer goods. We are adept at meeting the stringent standards required by each of these industries.

Answer:

We strive to accommodate the varied needs of our clients and can handle both small and large production runs. We do not strictly enforce a minimum order quantity but recommend contacting us to discuss the specifics of your project.

Answer:

We specialize in managing complex designs by leveraging our advanced die casting machines and our expertise in mold design and fabrication. Our process allows us to produce intricate parts with high precision and excellent surface finish.