Contract CNC programming outsources code creation for machining, enhancing efficiency, reducing costs, and accessing specialized expertise for operations.

Contract CNC Programming Definition

The definition is relevant to manufacturing applications that necessitate precision CNC machining. However, such tasks are typically outsourced not out of house, given cost, skill, and resource considerations. For example, businesses may adopt the definition as a concept that allows them to avoid hiring an in-house CNC programmer .

Key Components

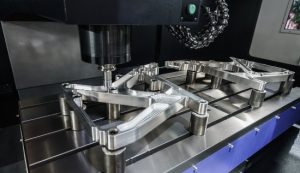

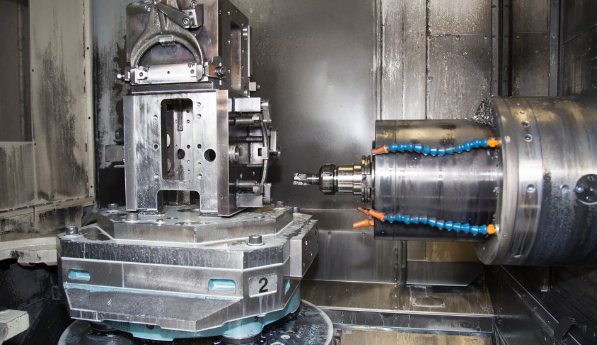

Contract CNC programming is the process of hiring an external CNC programmer to write the code necessary to operate a CNC machine. The specialists use a program designed for the purpose to write code for a machine that is read by a machine and tells it how to cut, machine, or shape metal, plastic, or composite materials to the desired designs .

The components of contract CNC programming are as follows

Programming software: The program is used to write or produce code that directs the action of CNC machines. The cost of the software is in the range of $2,000 to $20,000. The charges typically vary depending on the quality, sophistication, and complexity of the software.

Material specifications: the programmer writes code that makes machines create a specified product from specified materials. Material impact on tools or machine action may include material hardness or flexibility. Hardness and flexibility affect the tool path and cutting action in a way that a programmer has to adjust.

Machine parameters: specific machines require specific programming depending on the speed range and power rating. For example, CNC machines cut at 100 to 10,000 revolutions per minute and 5 to 50 brake horsepower with a range of variations . The parameters are adjusted to optimize production. The Role of Contract CNC Programmer

Contract CNC programmers have the following roles in manufacturing

- Translating design into code.

- Optimizing material production.

- Difference between in-house and contract CNC programming

- The following is a comparison of the two

Advantages of Contract CNC Programming for Manufacturing

The multiple benefits described above demonstrate the potential of contract CNC programming to promote the efficiency, cost-effectiveness, and innovativeness of manufacturing operations. These advantages, in turn, will help businesses maintain and gain competitive positions on the market due to the constant changes in demands and environments. Specifically, contract CNC programming benefits include the following factors:

Cost-effectiveness and Budgeting Opportunities

Contract CNC programming can significantly reduce costs across manufacturing component production. Given that the wages of CNC programmers usually range from $50,00 to $70,000 a year, not including bonuses, retirement plans, and training, the savings on salary and bonuses alone would present a substantial outcome.

Other non-salary savings include training and equipment purchasing

lack of need to buy expensive software for programming, the price of which may reach up to $2,000-20,000 and more depending on the complexity and sophistication of the software; and

extensive training for in-house initiatives as the contract staff continually develops skills without client investment.

Additionally, the savings can be reallocated within the business toward core areas like product development and marketing.

Implement Contract CNC Programming in Your Operations

Contract CNC programming can help take your manufacturing operations to the next level by boosting efficiency, reducing costs, and ensuring your products are of the highest quality. Here’s how to seamlessly implement this resource in your business processes:

Assess Your CNC Programming Needs

The first step to making good use of external expertise is to determine exactly what you need. Consider:

-

Project complexity. How intricate are your projects? Do they require a high degree of precision? Do they have complex geometries? For such projects, specialized contract programmers would be more suitable.

-

Volume and frequency. How much do you produce, and how often? For occasional batches or sporadic opportunities, hiring full-time staff is likely to be more expensive.

-

Technology gaps. Do you notice any gaps in technology in your operations? Most contract programmers provide access to the latest software and programming methods. You can close the gap without any capital investment. Find and Select the Right Contract CNC Programmer

The choice of this professional can make or break your operations. Here’s what to consider

-

Expertise and experience. How experienced are they? Are they familiar with your kind of work? How can their expertise improve production efficiency?

-

Portfolio and references. Take a look at their portfolio and find out if they have any references. A reliable contract programmer should have a portfolio and several reputable references.

-

Cost structure. What are their rates? While competitive pricing is important, it is equally important to understand what the costs cover to avoid hidden charges. Implement Contract CNC Programmers in Your Workflow

Smooth integration of a contract programmer into your workflow is essential. Here’s how to make it happen

-

Communication channels. Establish a line of communication. This can be any form including regular updates or a project management platform.

-

Data sharing and security. Ensure you have proper data-sharing protocols. This information is sensitive, and the security of your designs or proprietary information is non-negotiable.

-

Feedback loops. Develop some feedback mechanisms. This can ease tension in the working relationship. Monitor and Manage Contract CNC Programming ProjectahoConsidering areas

Achieving Peak Performance with Contract CNC Programming

When optimizing your manufacturing operations with contract CNC programming, it is vital to plan strategically, utilize specialized expertise, and keep yourself informed about the most recent industry trends and technologies. The following approaches will allow you to continuously improve your operations while keeping the quality high:

Strategies to keep CNC Programming Continuously improving

linking shop floor performance back to the programming team can prove to be a lucrative solution for dramatically increasing production speed and improving material utilization – companies’ reports indicate a 20% decrease in machining time and 15% loss reduction from analyzing recent project data and duly optimizing tool paths and specific cut parameters Key Strategy: Lean manufacturing principles for CNC programming processes and waste reduction tactics. Actionable Insight . Lean manufacturing Focus your contract CNC programmer’s training on cutting-edge software and machining innovations, such as adaptive machining, which can autonomously tune parameters for optimal efficiency during operation

When to employ contract CNC programming to complete tough projects?

When faced with complex projects which demand unique skills or high precision, few machining companies can justify hiring new programmers full-time. Thousands of contract CNC programmers have a varied experience in a wide variety of industries, which they are willing to put to use on your work for a one-time cost. Benefit: a programmer who specializes in titanium machining could reduce wear on your tools and machining time by up to 30% compared to a general programmer. This knowledge is worth tapping into for dangerous, delicate, or highly precise parts.

Ensuring Part Quality and Precision

When working with CNC programmed parts, it is imperative to maintain the highest standards of quality and precision. Rely on contract CNC programming on the following:

QA processes: simulate programs before machining and check every part afterward. If your dimensions are off by more than 0.0005 inches, you need to change something. Contract CNC programmers will test their own parts with CMMs and lasers to ensure they are perfect Custom Machining: The improvement in machining optimization can lead to vast efficiency gains and a proportional increase in part precision, better for your part’s performance and lifespan . .CppTypeDefinitionFuture of CNC Programming and Contractual Engagement

As AI and machine learning continue to develop and improve, CNC programming and contractual engagement in manufacturing will likely take a different turn for the better in the future.

Trending To avoid unexpected downtime costs, AI will inform you when your machines are about to fail, saving you tens of thousands of dollars in the long run. Increased productivity: AI technology could empower factories to produce pieces of a higher quality and at a faster rate than ever before.