The cost of a CNC machine varies by model and features, with small CNC lathes ranging from $15,000 to $75,000, and high-end five-axis CNC milling machines costing up to $450,000.

Types of CNC Machines

CNC lathes are one of the most common CNC machines, mainly used for machining rotationally symmetrical parts. They feature high precision, high efficiency, and a high degree of automation, capable of completing multiple machining steps in one go. The machining diameter range is typically between 10mm and 500mm, and the machining length can reach up to 3000mm. CNC lathes are used in the automotive industry to machine various shaft parts, such as drive shafts and crankshafts, in the machinery manufacturing industry to produce various high-precision rotating parts, and in the aerospace field to machine shaft parts of aircraft engines.

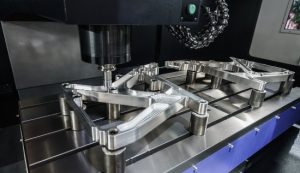

CNC milling machines are used for machining complex planes and curved surface parts, widely used in mold manufacturing, mechanical processing, and aerospace fields. The multi-axis linkage capability of CNC milling machines allows for high-precision three-dimensional machining. The machining range can vary from 200mm x 300mm to 2000mm x 4000mm, depending on the specific model and application needs. In mold manufacturing, CNC milling machines are used to create various complex mold cavities and cores; in mechanical processing, they are used to manufacture complex parts such as gearboxes and complex curved surface parts; in the aerospace field, they are used to machine the complex curved surfaces of aircraft wings and fuselages.

CNC grinding machines are mainly used for high-precision surface machining, commonly used in mold manufacturing and precision parts processing. CNC grinding machines offer high precision and high surface quality, typically achieving a machining accuracy of 0.001mm and a surface roughness of Ra0.2μm or less. In mold manufacturing, CNC grinding machines are used to process high-precision mold surfaces; in optical parts processing, they are used to manufacture high-precision optical lenses and mirrors; in high-precision bearing manufacturing, they are used to process high-precision bearing inner and outer rings and rollers.

CNC boring machines are primarily used for machining large-size holes, especially suitable for the manufacturing of heavy machinery and large equipment. They feature the ability to machine large-size, high-precision bore diameters, typically used for machining large holes with diameters exceeding 500mm. CNC boring machines are used in heavy machinery manufacturing to machine large engine blocks and ship components; in energy equipment manufacturing, they are used to process key components of large turbines and power generation equipment; in construction machinery manufacturing, they are used to machine main structural parts of large cranes and excavators.

CNC EDM machines are used for machining high-hardness materials and complex-shaped parts, widely used in mold manufacturing and the aerospace field. They are characterized by the ability to machine any conductive material regardless of material hardness, typically used for machining complex mold cavities and fine parts, with machining accuracy usually reaching 0.005mm. In mold manufacturing, CNC EDM machines are used to process high-hardness mold cavities and fine structures; in the aerospace field, they are used to machine high-precision turbine blades and complex engine parts; in the electronics industry, they are used to process high-precision electronic connectors and micro parts.

Price Range of CNC Machines

Well-known manufacturers of domestic brands include Guangzhou CNC, Huazhong CNC, and Dalian Machine Tool. Guangzhou CNC small and medium-sized CNC lathes are priced at 100,000-300,000 yuan each. Larger types cost about 1.5 million to one million five. Huazhong CNC has a cost of 200,000-500,000 yuan for each piece in its CNC grinding machine set and ranges from 300,000 to 800,000 yuan. For example, Dalian Machine Tool‘s CNC boring machines are priced from 500 thousand to 2 million yuan.

CNC machines mostly cost quite less than CNC UK, but imported brands are generally of a higher price. Germany Siemens, Japanese FANUC, and U.S. Haas represent the advanced five-axis CNC machining center of Siemens ranging from 1 million to 3 million yuan per set; while one simple-type high-precision numerical control lathe could reach from RMB800 thousand up to RMB2 million. Reports show that Italy’s three times annual production value can be evaluated as “the world”. CNC EDM machines from Fanuc are priced between 600,000-1.5 million yuan, whereas CNC lathes and milling systems from Haas come within a range of over 700,000-2 million yuan.

Various CNCs are also in different price brackets. A simple CNC lathe can be sold at a price of over 100,000 yuan without much effort; a high-capacity five-axis rotating work table (known for its stiffness and weight), the direct drive unit, etc., may fetch as little as less than drive technology. The price is usually between 200,000 and 800,000 yuan for CNC grinding machines. The cost range of a single drill-type CNC boring machine varies widely – generally from 500,000 to 2 million yuan. High-precision CNC EDM machine tools are priced 600 to 1.5 million yuan.

These are all the things to consider when purchasing a CNC machine for your enterprise, especially what is required and how much you can manage. Top CNC lathes or milling machines are the best choices if production of parts is in mass quantities. If the company is machining high-precision complex parts, a high-end five-axis CNC milling machine or other specialized equipment such as a CNC EDM will make more sense.

Factors Determining CNC Machine Prices

Brand – The brand is a big factor affecting the pricing of folding knives. Especially Siemens and Fanuc machines are expensive. For example, a five-axis CNC milling machine of Siemens can price between 2-3 million yuan, while Fanuc‘s high-end lathe prices at around 120k yuan.

Functions are also a significant factor in manipulating the prices. The cost of the simplest CNC lathes is around 100,000 to 500,000 yuan, while five-axis linkage for NC milling machines can be as high as 3 million yuan. High-performing capacities (for example, automatic tool changer systems, high-speed machining capabilities, and full-fledged smart control systems) are additional features that will raise the cost of CNC machines. The advantage of CNC machining centers is the high repeatable positioning accuracy and fast hand spindle and automatic tool change system, which generally costs more than 1 million yuan.

Size and technical details also contribute to the overall appeal of prices. The prices of small CNC lathes and milling machines are relatively cheap, while larger ones such as horizontal boring machines or gantry machining centers are much more expensive. CNC milling machines with a machining range of 200mm x 300mm to 2000mm x 4000 mm have large price differences, and larger gantry-type processing centers can reach more than 500 million yuan or even higher. The price of common CNC grinding machines is generally between 200,000 and 800,000 yuan (cooling liquid model can be more expensive), and high-precision CNC grinding machines can cost more than one million yuan.

Market demand and supply relationships also affect CNC machine prices. For instance, high-precision CNC machines have robust demand in automotive manufacturing and aerospace fields, driving prices higher. Global supply chain changes can also influence CNC machine prices, and a scarcity of necessary components may cause prices to rise.

Additionally, the specific configurations and extras influence the price. Standard build CNC machines are relatively affordable, but premium features like a high-precision measuring system and cooling and protective covers will cost considerably more. An increase of about 20% to 30% more for CNC grinding machines equipped with precision-measurement systems can be expected.