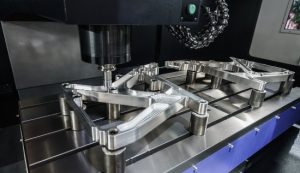

Medical CNC machining achieves micron-level precision through numerical control technology, maintaining error control within 0.001 millimeters when making heart stents. It improves product consistency and reliability, with a defect rate of less than 1% in mass production.

High Precision and Complex Geometries

Medical CNC machining, through numerical control technology, can achieve precision at the micron level, ensuring the accuracy of medical equipment and instruments. When making heart stents, the error control must be within 0.001 millimeters, as even minor errors can affect the functionality of the device and patient safety. CNC machine tools use CAD/CAM software for design and programming, allowing precise machining according to design requirements. This highly automated process not only improves production efficiency but also reduces human errors. When making artificial joints, CNC machining can accurately reproduce complex three-dimensional shapes, ensuring each part fits perfectly.

- Handling Complex Geometries: Medical equipment such as endoscopes and surgical robots require complex internal structures and high-precision external shapes. CNC machining can handle these complex geometries without compromising precision, ensuring the functionality and performance of the equipment. When making tiny parts of endoscopes, CNC machining can complete up to 30 different complex shape processing steps while maintaining high precision. Specifically, some parts of an endoscope may have a diameter of only 0.5 millimeters but a length exceeding 100 millimeters.

- Improving Product Consistency and Reliability: In large-scale production, CNC machining ensures that every part maintains the same specifications and quality. When producing a batch of 1,000 pacemaker parts, CNC machining can ensure that the dimensional error of each part does not exceed 0.002 millimeters. For mass-produced medical devices, such as disposable surgical tools, CNC machining can ensure a pass rate of over 99% for each batch, significantly reducing the defect rate.

- Application of Precision and Complex Shapes: In making complex orthopedic implants, such as intervertebral disc prostheses and hip joint prostheses, CNC machining technology can achieve machining precision of up to ±0.005 millimeters. This high precision not only ensures a perfect fit of the implants but also extends their lifespan, reducing the risk of postoperative complications. A leading medical device company using CNC machining technology to make hip joint prostheses reports an average product lifespan of over 15 years, extending the lifespan by about 25% compared to traditionally manufactured prostheses.

Material Diversity and Biocompatibility

Medical devices are made of stainless steel, titanium alloys, aluminum alloys, cobalt-chromium-molybdenum alloys, and high-performance plastics. Introduction and application of orthopedic implants that use titanium alloy will present the basic knowledge of ti for medical applications, including their biocompatibility with human tissues in vivo and one model used to measure at the molecular level some parameter related to early stages osseointegration.

- Application of Titanium Alloys: They are known to be biocompatible and provide a high standard for both corrosion resistance. The precision of titanium alloy bone screws manufactured by CNC machining can reach 0.005mm, which is equivalent to the level of hairdressing in our usual words, ensuring that after implantation into human bones, the screw fits perfectly with bone tissue and reduces postoperative infections and rejection reactions. Average patients using titanium alloy bone screws see 30% shorter postoperative recovery time.

- Stainless Steel Uses: The applications of stainless steel are innumerable. Stainless steels are most commonly used material to fabricate surgical instruments and dental equipment due to their anti-corrosive properties and strength. Stainless steel surgical scissors are subject to high demands on the sharpness and durability of their blade parts. The blade thickness error of a surgical instrument is less than 0.002 mm in CNC machining, which can greatly improve longevity and operational accuracy.

- High-Performance Plastics Used for Application: Some devices and components in the medical field need to use high-performance plastics, such as Polyether Ether Ketone (PEEK) and Poly Methyl Methacrylate (PMMA). PEEK material for implants used in spinal fusion surgery is processed via CNC machining. PEEK spinal implants have an over 95% success rate.

- Impact of Material Diversity on Production Efficiency and Costs: CNC machining technology can handle a variety of materials without regard to processing techniques. All the complex shapes of cutting and polishing steps in cobalt-chromium alloy dental restorations produced by CNC machining can be completed at one time; previously, multi-pass processing was required due to the complexity, causing time-intensity and costliness. CNC machining shortens the production cycle by about 40% and reduces production costs by approximately 30%, compared with traditional processing methods.

- Importance of Biocompatibility: To manufacture precise and intricate medical components using CNC machining, the material must be biocompatible. Pacemaker cases are traditionally made from titanium alloys or medical-grade stainless steel. These materials must exhibit excellent biocompatibility to avoid any reactivity with heart tissue or cause immune response. Materials with good biocompatibility can shrink the rate of postoperative complications to even fewer than 5%.

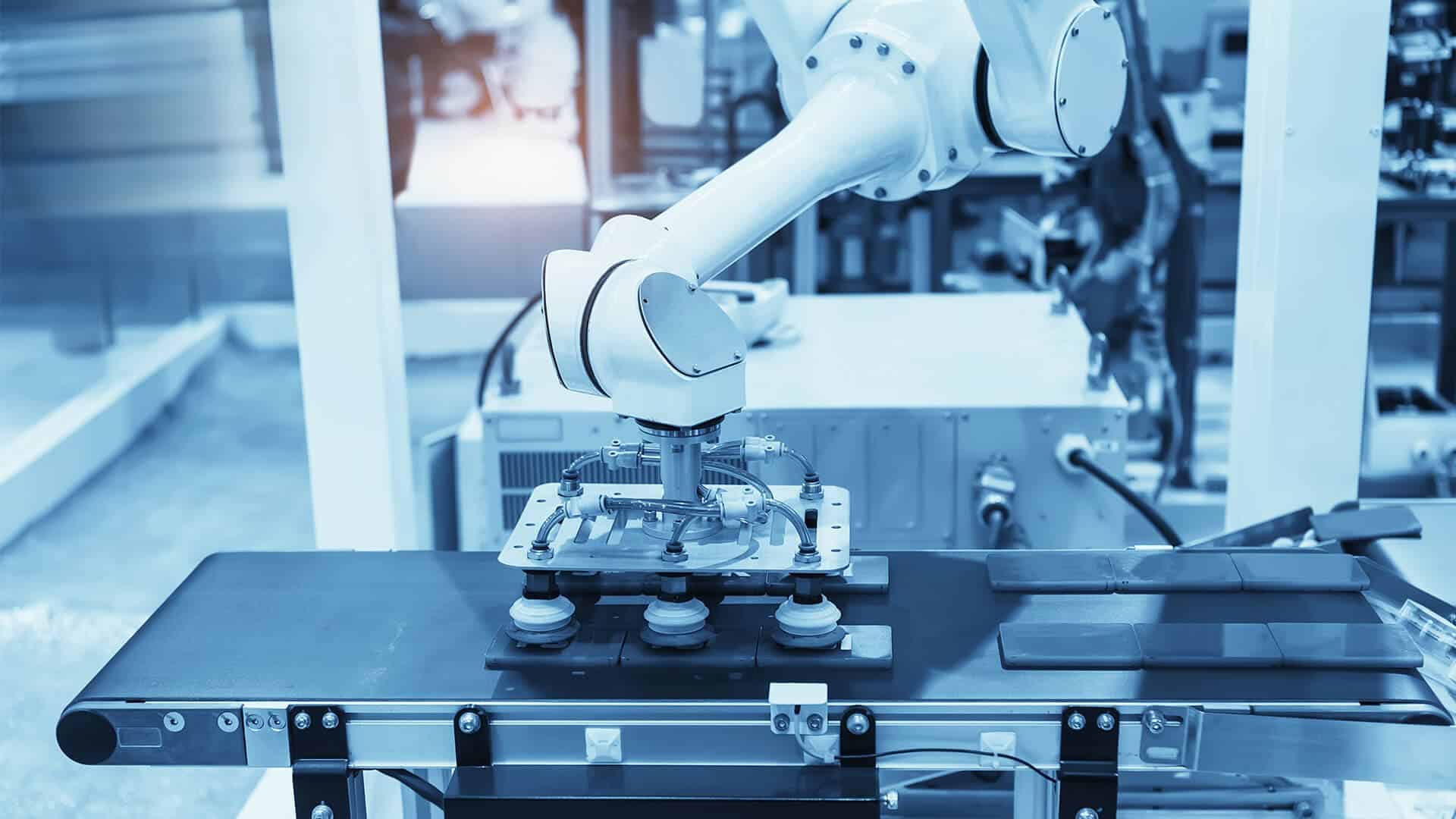

Prototype Design and Rapid Production

Medical CNC machining can quickly transform design drawings into actual products in prototype design and rapid production, greatly shortening the development cycle and speeding up the market launch of medical devices. A complex medical device prototype can be completed in just a few days from design to completion, while traditional methods may take weeks or even months.

- Rapid Iteration of Prototype Design: CNC machining allows designers to quickly iterate prototypes. A medical device company, when developing new orthopedic implants, reduced the prototype production time for each design modification from the traditional two weeks to within 48 hours through CNC machining.

- Data Support: A company, through CNC machining technology for prototype design, shortened the development cycle of new products from the original 18 months to 8 months, saving about 55% of the time. The high efficiency and precision of CNC machining reduced the production cost of each prototype by about 30%.

- Flexibility of Mass Production: Traditional production methods often require expensive molds and long preparation times, while CNC machining can directly produce from digital models, greatly reducing the preparation time. A company producing heart stents, through CNC machining technology, shortened the preparation time for mass production from 6 weeks to 1 week, with a pass rate of over 98% for each batch produced.

- Process Efficiency Improvement: The high efficiency and flexibility of CNC machining make it particularly outstanding in producing small batches and customized medical devices. The production of customized surgical guides, through CNC machining, can complete the entire production process within 24 hours, while traditional methods may take several days or even weeks. Using CNC machining for customized surgical guides reduces the average production cycle by 70% and the cost by about 40%.

- Real-world Applications: When producing a new type of implant, a company completed the entire process from design to market launch in just three months through CNC machining. During this process, they manufactured over 50 prototypes, with each prototype costing about $500, far lower than the $2000 using traditional methods. The final product was launched six months earlier than expected, with good market feedback and sales exceeding $5 million in the first year.

- Quick Response to Market Demand: The rapid production capability of CNC machining enables medical device companies to quickly respond to market demand and customer feedback. After receiving customer feedback on improving surgical instruments, a company completed the design improvements and new product production within a week through CNC machining technology. This rapid response capability not only improved customer satisfaction but also enhanced the company’s competitiveness in the market.