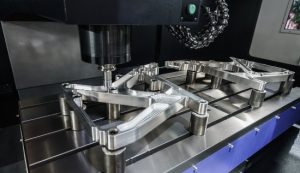

When selecting the right 3D CNC machining equipment, consider the material type, part size, and precision requirements. For instance, choose equipment with over 10,000 RPM for processing aluminum, and a worktable size of at least 1000mm x 500mm for large parts. Also, evaluate the cost, brand reputation, and after-sales support.

Assessing Your Needs

When choosing 3D CNC machining equipment, first remember the type of material you need to process. Common materials include aluminum, steel, stainless steel, titanium, plastic, etc. For machining aluminum, selecting equipment with an RPM above 10,000 helps improve processing efficiency. For harder materials like titanium, a spindle motor with a torque above 40 Nm is necessary.

For processing large parts, choose equipment with a worktable size of at least 1000mm x 500mm. For smaller parts, a smaller worktable size is sufficient. Processing accuracy typically ranges from 0.01mm to 0.005mm. Industries requiring high precision, such as aerospace and medical devices, need equipment with grating scale feedback, achieving accuracy up to 0.002mm.The faster the machining speed, the higher the production efficiency, but it may also affect the stability of the equipment and tool life. Equipment with a feed rate above 2000mm/min is suitable for mass production, while slower feed rate equipment is suitable for high-precision single or small batch processing. In mass production, increasing the feed rate by 10% can increase production efficiency by 15%.

To thoroughly assess your needs, create a requirement list, including processing materials, sizes, accuracy, speed, etc. Then, search for corresponding equipment parameters based on this list. For example, a certain equipment’s parameter sheet indicates it is suitable for aluminum and stainless steel, with a worktable size of 1200mm x 600mm, processing accuracy of 0.005mm, and a feed rate of 2500mm/min.In cost evaluation, consider the initial purchase price, maintenance costs, operating costs, and tool replacement frequency. The price range of high-end 3D CNC equipment is usually between $100,000 and $500,000, with annual maintenance costs approximately 2-5% of the equipment price. High-speed machining causes faster tool wear, requiring 20-50 tool replacements annually, with each tool costing $50-200.

Choosing the Right Equipment Type

First, consider common brands and models in the market. The Haas VF series, Mazak VCN series, and DMG Mori CMX series are well-known brands, with prices ranging from $80,000 to $300,000. The Haas VF-2 model is suitable for small to medium-sized part processing, priced around $100,000, while the Mazak VCN-530C is suitable for larger part processing, priced around $250,000.In addition to the equipment price, most CNC equipment requires dedicated software for programming and control. Haas equipment commonly uses the Haas CNC control system, priced between $10,000 and $20,000. DMG Mori equipment uses the CELOS system, costing about $15,000. These software programs require initial investment and regular upgrades and maintenance, with annual maintenance costs approximately 10-15% of the initial cost.

High-performance equipment usually requires high-quality tools and maintenance services. Each high-performance tool costs between $100 and $500, with an annual replacement of 50-100 tools depending on the machining frequency. Annual tool and maintenance costs may account for 5-10% of the initial equipment purchase price. Specifically, if the equipment price is $200,000, annual maintenance and tool costs would be about $10,000 to $20,000.The price of consumables such as coolant and lubricating oil used in the machining process is about $10-30 per liter, with annual usage reaching 200-500 liters. The annual coolant consumption cost may be between $2,000 and $15,000, depending on equipment usage frequency and material types. The annual usage of lubricating oil is about 100-300 liters, priced at $20-50 per liter, so the annual lubricating oil consumption cost is about $2,000 to $15,000.

Regarding specific equipment models and applicable scenarios, the Haas VF-2 is suitable for medium-sized factories with a worktable size of 914mm x 356mm and a spindle speed of 8100 RPM. For enterprises requiring higher processing accuracy, the DMG Mori CMX 1100 V is an ideal choice, with a processing accuracy of 0.002mm and a spindle speed of up to 12,000 RPM. Additionally, the Mazak VCN-530C has a worktable size of 1300mm x 550mm and a spindle speed of up to 10,000 RPM, suitable for large parts processing needs.Different brands and models of equipment also vary in lifespan and maintenance cycles. Haas equipment typically has a long lifespan of over 10 years, with longer maintenance cycles requiring routine maintenance every 500 hours. Mazak equipment has a relatively higher maintenance frequency, needing maintenance every 300 hours, but offers higher machining speed and efficiency. DMG Mori equipment has a lifespan of 8 to 12 years, with a 400-hour maintenance cycle, ensuring high precision and efficiency.

After-Sales Service and Support

After-sales service and support are crucial when choosing 3D CNC machining equipment. First, consider the brand’s reputation and customer reviews. Well-known brands like Haas, Mazak, and DMG Mori enjoy good market reputations, with customer satisfaction typically above 80%. According to customer feedback, these brands excel in equipment performance and after-sales service. Haas has over 170 service centers worldwide, resolving over 95% of customer issues annually. Mazak provides 24/7 technical support hotlines to ensure customers receive help at any time.

Many brands offer comprehensive technical training, including on-site training and online courses. Haas’s training courses include equipment operation, maintenance, and troubleshooting, costing about $500-1000 per person. DMG Mori offers more comprehensive training, including advanced programming techniques, costing about $2000 per person. For novice operators, Mazak provides free basic training and discounts for advanced courses, ensuring all operators are proficient in using the equipment.Haas offers a two-year or 4000-hour warranty, including parts and labor. Mazak’s warranty is one year or 3000 hours, with extended warranties available for an additional 5-10% of the equipment price. DMG Mori’s warranty is three years or 5000 hours, including a free one-time annual maintenance service.

Depending on equipment usage frequency and materials processed, annual maintenance costs are about 3-7% of the equipment price. For a $200,000 piece of equipment, annual maintenance costs might be $6,000 to $14,000. Haas’s maintenance packages include regular inspections and necessary part replacements, costing $5,000-10,000 annually. Mazak’s maintenance services are more detailed, including quarterly equipment inspections, costing about $8,000-12,000 annually.High-quality 3D CNC equipment typically has a lifespan of 10-15 years. Regular maintenance and care can significantly extend equipment lifespan. According to statistical data, regular maintenance can reduce equipment failure rates by 40%, thus decreasing downtime and improving production efficiency.