Sheet metal processing features easy forming, excellent conductivity, corrosion resistance, and lightweight high strength. For example, a 2mm aluminum plate can be CNC bent to 90 degrees, copper conductivity is 5.96×10⁷ Siemens, and 6061 aluminum alloy’s corrosion resistance increases by 40% after anodizing.

Easy to Form

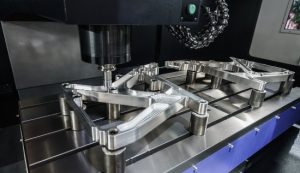

The forming process is highly operable and flexible. A 2mm thick aluminum plate can be bent to a 90-degree angle in one go with CNC, achieving a forming efficiency of about 95%. Compared to other materials, sheet metal forming time is reduced by 40%.

There are various choices of sheet metal materials, such as steel, aluminum, and stainless steel. According to “Manufacturing Daily,” sheet metal processing enterprises have reduced the forming cost of each product by 20% through optimizing process flows, resulting in an annual profit increase of 15%.

Companies like Foxconn and Huawei are applying advanced sheet metal forming technologies to improve the quality and production efficiency of household appliances. A senior president of Foxconn once said, “We invest more than 50 million yuan annually in forming processes to ensure competitiveness in the global market.”

It can also combine laser cutting and punching methods with this sheet metal forming. For example, using laser cutting technology, the cutting precision of sheet metal parts can be controlled within 0.1mm.

Excellent Conductivity

Among metal sheet materials, copper and aluminum have the best conductivity. For example, copper is one of the highest conductive metals, with 5.96×10⁷ Siemens per meter. Due to its extremely high current-carrying capacity, it is very suitable for use as wire terminals and cables in circuit boards.

Using copper as the conductive material increases the energy transmission efficiency of electrical equipment by 20%. For household appliances such as air conditioners and refrigerators made of conductive copper materials, it can save up to 15% of electricity bills.

A Huawei engineer mentioned, “The choice of conductive materials is crucial in all our electronic devices. Copper’s excellent conductivity ensures efficient and long-lasting operation.” This conductivity not only improves device efficiency but also reduces the frequency of replacing and maintaining more expensive components.

Aluminum has a conductivity of about 3.5×10⁷ Siemens per meter, but its lightweight makes it the preferred material for aerospace applications and automobiles. New aircraft extensively use aluminum alloys because aluminum alloys have improved not only in conductivity but also in factory weight. Boeing usually adopts this system.

Corrosion Resistance

Stainless steel and aluminum alloys exhibit excellent corrosion resistance in different environments and are typical sheet metal coating materials. For example, 304 stainless steel has a corrosion-resistant lifespan of more than twenty years.

According to the Industrial Metals Journal, an offshore drilling platform made of stainless steel weighs as much as 1,500 tons, significantly extending its service life and reducing annual maintenance costs by about $1 million.

Aluminum alloys also have advantages in corrosion resistance. For example, after anodizing, the corrosion resistance of 6061 aluminum alloy can be increased by about 40%. Boeing’s new aircraft bodies extensively use this aluminum, increasing corrosion resistance while also reducing body weight.

A Haier engineer pointed out, “Our household appliances use stainless steel casings, which are not only aesthetically pleasing but also effectively prevent corrosion from moisture and acidic or alkaline substances, extending their lifespan.” In the home appliance industry, this means resistance to corrosion and stability even in high humidity environments.

Surface coating and electroplating processes can also improve the corrosion resistance of sheet metal materials. For example, galvanized steel sheets have a corrosion resistance more than 50% higher.

Lightweight and High Strength

Sheet metal materials are widely used in aviation, automobiles, construction, and other industries due to their lightweight and high strength. Take aluminum alloy, for example; its density is only 2.7 grams per cubic centimeter, but its strength is as high as 450 megapascals (MPa), far higher than most traditional materials.

Boeing’s data shows that aluminum alloys reduce the weight of airplanes by 15% and fuel consumption by 20%.

Sheet metal materials are also indispensable in the automotive industry, from structure to auxiliary lightweight high-strength products. The body is composed of a large amount of high-strength aluminum alloy, reducing the weight by 10% compared to steel structures, and improving energy absorption by nearly one-third, providing better protection for passengers.

Sheet metal materials also have their place in the construction industry because they are lightweight and strong. A familiar example is the Burj Khalifa in Dubai, whose exterior walls use a large amount of high-quality stainless steel and aluminum alloys, providing structural strength while minimizing load.

Renowned architect Norman Foster once commented, “Modern architecture increasingly relies on lightweight and high-strength materials, which not only make buildings more robust but also give them more design flexibility and aesthetic value.”