Explore innovations in CNC technology, including advanced software, high-precision tools, automated QC, IoT integration, and green manufacturing that are revolutionizing the industry

Advanced Software Integration

This marks a large step toward the advancement of smarter, more autonomous production environments in the adoption of more sophisticated, software-based technologies with CNC machining. These software systems add features to CNC machines like predictive maintenance, more automation, and greater cutting accuracy perfect for industries that require precision and efficiency.

Machine Monitoring and Feedback in Real Time

So this is how it worked, a CNC system is a software oriented equipment that lets you monitor, reveal and plan in parallel. This allows operators to correct the process as needed, which makes the machine process more efficient and the output quality better. With these solutions, Siemens SINUMERIK CNC systems can provide insight into performance of machines and allow to reduce downtimes and boost operational throughput. According to the reports this can increase machine utilization by 20% or more.

Enhanced User Interfaces

General – It has all sorts of intuitive user interfaces, which are making the complex CNC machinery much easier to operate. Several software providers, including Mastercam and SolidWorks, have relaunched their user interfaces with an eye toward more widespread user adoption, lowering the learning curve for new operators and shrinking training times. The interfaces commonly include drag and drop toolpath visualization, and are designed to simplify the process of programming more complicated maching operations.

A CAD/CAM Solution for Integration

Currently, the design to production workflow has been entirely changed with the integration of CAD/CAM software with CNC machines. You are able to send your 3D models directly to the CNC machines from programs like Autodesk and the machines will cut the model rapidly and accurately, as per the specified cuts(JSONObject, 2018). This has minimized the errors that might happen at the time of translating RMJX files into the production process. One user stated that this has shortened her time from design to production by 30%.

Predictive Maintenance Solutions

The more advanced software integration, predictive maintenance systems can even anticipate cutting tool wear-out before they do These systems can anticipate the wear and tear on key components and will prompt maintenance services, by examining the data of sensors that are installed inside the CNC machinery. Some examples include FANUC predictive maintenance technology that has been proven to decrease unexpected down time by 45%, resulting in more predictable production schedules.

Software Solutions Customized for Your Needs

Finally, perhaps the best advancement is the adaptability of CNC software for it can be altered to suit the industry with the same level of ease. Tailoring CNC operations to unique production demands with custom software solutions allows businesses to maximize processes and minimize waste. For example, certain industries, including woodworking and aerospace, can now access high-end software configurations that are specifically designed for the materials they use and the level of precision the industry demands. This flexibility increases operational efficiency and improves product quality as well

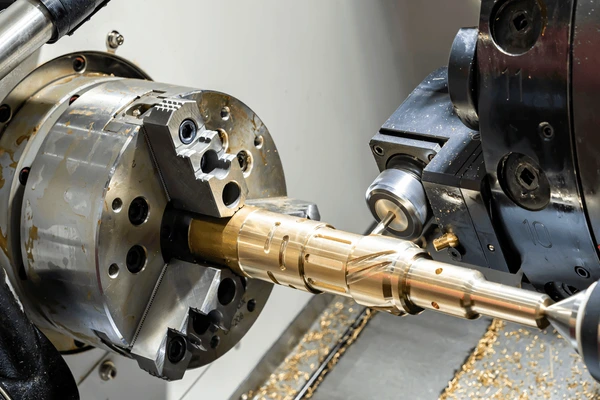

High-Precision Tools

Today, thanks to the development of high-precision tools, CNC machining has made it possible for manufacturers to achieve an unbeatable degree of accuracy and production quality. For good reason- in the aerospace and medical manufacturing industries, where precision is paramount, these tools are an absolute necessity. Thanks to companies like Sandvik and Kennametal who have been instrumental in developing tooling technology, we can achieve accuracies in the microns, consistently.

Tool Calibration Automation

Better automated calibration has improved the accuracy of CNC machining. Laser measurement and feedback loops adjust tool settings as needed in real-time, with this feedback often integrated directly into the CNC equipment. Similar to Makino CNC machinery whose automatic calibration systems have been known to cut setup times by as much as 15%, all while keeping machine accuracies in check without human assistance.

Durability of Tools and Material Innovation

For example, the development of new materials such as polycrystalline diamond (PCD) and cubic boron nitride (CBN) has dramatically increased the lifespan of CNC tools. Not only are these materials harder and more abrasion-resistant than conventional carbides, they also dissipate heat better, which means they are less likely to fail when machining at high speeds. In high-volume production environments, this transition has been critical, as the lifespan of a tool correlates directly with the efficiency of its operation.

Graph Database With Machine Learning Integration

CNC Tooling Trends : Integration of Machine Learning Algorithms for optimizing tool paths and predicting tool wear with new age tool resharpening facilities This is a real-time data and predictive analytic technology that allows us to make preemptive changes to the process which minimizes downtime and increases product quality. Furthermore, companies such as Okuma and Haas recall cases in which machine learning extended the life of the tool by more than 40%, since it dynamically adjusted the operating parameters to the current properties of the tool and the machinable material.

Affect on customs or complex designs

Additionally, the accuracy of modern CNC tools have broadened custom complex design options. This capability is especially beneficial in industries such as custom automotive parts manufacturing, allowing very fine designs that even a few years ago were impossible to manufacture. Even the most unique parts are held to stringent quality standards by the high-repeatability capability to fabricate highly accurate, intricate geometries.

Automated Quality Control

In CNC machining automated quality control (AQC) systems are essential to maintain a high level of quality hand in hand with efficiency.splice protection. Integrated by systems that incorporate sensors, cameras and sophisticated algorithms to identify compliance with quality criteria throughout all machining processes.

Machine-Vision-Systems Integration

CNC quality control is also driving some of the most advanced machine vision systems. These systems are made of high resolution cameras and image processing software processing carried out in real time to inspect machined parts. For example, the Keyence vision system allows precision CNC setups to be used to detect dimensional and surface defects to an accuracy of 0.0001 inches. Such precision is necessary in industries like semiconductors, where the smallest imperfection can make a chip useless.

Process Tuning with Real Time Data Analysis

Immediate corrections can be made while machining with AQC systems’ real-time data analysis tools. These tools automatically change the cutting speed, feed rate, tool path, and other parameters by collecting telemetry from various sensors. Siemens’ SINUMERIK Integrate Run MyProcess software dynamically alters machining parameters based on tool wear detected during operations to ensure consistent, high-quality parts.Interior view of the tube laser cutting cell.

Statistical Process Control Integration

Automated Quality Control with Statistical Process Control (SPC) This SPC software module is available acquisition can be used to monitor the progress of the process and become increasingly sensitive to a change that may exceed the set quality limits. With this integration, you will be able to identify potential problems early, thus avoiding expensive issues. SPC tools have enabled manufacturers to reduce scrap rates by up to 30% leading to increased production efficiencies.

Automated Feedback Loops

Modern AQC systems have automated feedback loops built-in that, in turn, to give self-corrective measures within the CNC machines. These loops use the data obtained from sensors and cameras to control the data into the system to optimize the machining process parameters. This configuration not only reduces human error, but also improves production speed. For instance, automotive manufacturing plants have deployed automated feedback systems within high-precision CNC machines, which have achieved reductions of over 50% in defect rates.

Enhanced Traceability

AQC systems offer advanced traceability benefits which provide detailed tracking of each part that has been through the CNC machine. This is key for sectors which must obey tight safety and quality norms (aviation, medical, etc) Traceability systems need to inform you where every part is and if said part is meeting the required specifications. These industries have achieved better compliance rates and less recall instances by being able to ensure that only parts that have passed all quality checks throughout the supply chain componentWillMount

IoT Connectivity

With IoT connectivity, CNC machining has evolved into an extremely well-integrated and communicating ecosystem. This allows the machines to perform not only work, but also to communicate and carry out operations using constant data interaction. IoT Technology in CNC IoT technology within the CNC systems helps in the real-time monitoring, predictive maintenance and hence ultimately leads to streamlined and efficient production processes.

Real-Time Machine Monitoring

IoT-enabled CNC allows real-time monitoring to be from machine performance and working conditions. A case in point is Mazak who have adopted IoT systems that track machine usage, speed of operation and frequency of errors, giving a full picture of the machine’s health. Those systems can reduce downtime up to 20% because they can support both predictive maintenance and setting up adjustments.

False-positive in Predictive Maintenance using ML

Predictive maintenance, driven by machine learning algorithms, is one of the most important advantages of IoT in CNC. Systems of this type can also predict when a given piece of equipment may come up for failure, basing on the data collected from individual occurrences of machine operations. An example is Fanuc’s Zero Downtime (ZDT) technology which uses IoT to forecast CNC component failures and to minimize unplanned downtimes by up to seventy percent. Not only is this a cost-saving measure, it also ramps up production reliability.

Automated Resource Allocation

Automated resource allocation with IoT connectivity ensures CNC machines function at peak efficiency. The power usage, tool path, and material feed rates can all adapt to real-time data to achieve optimized productivity while decreasing waste. As an example, there is the Celos system from DMG Mori, which ensures optimum utilisation of resources, increases overall energy efficiency and in the best cases reduces material costs by up to 30 per cent.

Supply Chain Management Connectivity

Beyond the machines, IoT connectivity is fed integratively into overarching supply chain management systems. The sync production schedules and inventory management not only for production materials on time but helps produce finished goods in right condition. For example, companies such as Siemens have created software solutions targeting the integration of IoT data from CNC machines into supply chain logistics to improve the responsiveness and agility of manufacturing operations.

Advanced Data Security Features

This comes with an added demand for tighter security, as data is now being passed around in increasing amounts. The new-age CNC machines, which also have the added advantage of IoT connectivity, have been built in with the most stringent levels of cybersecurity to safeguard the critical, and often high-stakes, operational data housed within the machines. This part of the security is essential – for example, the defense and aerospace businesses need certificated proof of data integrity, so this part of the security is very much needed. By using stronger encryption and secure data channels, it can be ensured that his information stays secure and only authorized parties have access to it, which ensures the integrity of the manufacturing process.

Sustainable Production Practices

Sustainable manufacturing in CNC machining helps enterprises maintain a high production output while lowering carbon footprint. These practices, enabled by advanced CNC technology, include the use of eco-friendly materials, energy optimization, and waste recycling. While these are more or less good practices to prevent companies from regulatory leakage, they are also quite appealing to a more and more capricious population of eco-conscious consumers.

Use of Eco-Friendly Materials

Eco-Friendly Materials: A Major Shift in CNC Machining An instance is the use of biodegradable coolants by more and more companies rather than widely used petroleum-based coolants, that toxicifies nature far less. Others have also started incorporating recycled metals and composites into the processes. This method not only decreases the demand of raw materials required but also lowers the carbon footprint of manufacturing itself.

Improvements in Energy Efficiency

Another major breakthrough of CNC machining is energy efficiency. Contemporary CNC machines are constructed with a certain level of operating efficiency in which their energy efficacies are built-in, i.e. automatic shut-down and low-energy modes. For example, newer models from manufacturers such as Haas and Okuma have adaptive power systems that can scale the power draw based on workload, and reduce energy usage sometimes by up to 30% compared to older equipment.

Innovative Trash Disposal Systems

Waste disposal Get back Waste segregation with recycling has become more advanced with systems that separate scrap for easier reuse. CNC machining plants can easily classify various material categories thanks to automated sorting systems, which contributes to improve recycling procedures. So not only does these systems prevent waste but contribute to a large reduction in the costs related to disposing of your waste. According to the statement of some of the industry leaders, appropriate waste management techniques help to bring down the waste disposal costs till 50% as compared to others.

Less Toxic and Cleaner Solvent Consumption

CNC innovations also help reduce emissions and solvent use, advances in sustainable manufacturing. Modern CNC machines have improved ventilation systems compare with the old ones while machining, this greatly reduces airborne pollutants. Furthermore, the trend to water-based solvents or cutting with minimum quantity lubrication in the machining processes has significantly reduced the amount of toxic solvents being pumped into the environment.

Equipment Upgrades and Lifecycle Management

Automated lifecycle management and upcycling of CNC equipment are part of a sustainable process. They will upgrade the CNC equipment rather than replace it in order to keep up with new technologies by designing machines with upgradable components. This then means not only drives them to last much longer, but also an amount with landfill in relation to electronic waste. DMG Mori is also helping to elongate the lifespan of machinery equipment currently on the market by creating adjustable designs that allow parts to be replaced and upgraded more easily – effectively conferring a longer service life to equipment, which would otherwise have been quickly disposed of and replaced (upon a comparative new manufacturing process).