CNC modular tool systems offer increased flexibility, reduced downtime, cost efficiency, enhanced precision, and quicker response to production changes.

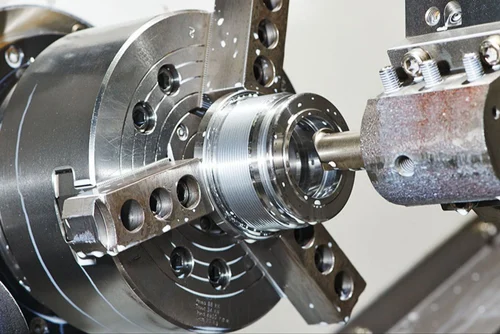

Versatile Use and Adaptability

The CNC modular tooling system is a prime example of adaptability and versatility in modern manufacturing environments. One of its primary advantages is the ability to quickly adapt to virtually any production requirement without significant downtime or additional expenses to “retool.” For instance, a clear demonstration of this adaptability is its application in the automotive sector. Vehicle manufacturers often have to produce different parts rapidly when the client would like a given model to be delivered quickly.

Changeovers

A prominent example is an automotive parts supplier which implemented CNC modular tooling for all of its production lines. According to the information presented by the manufacturer’s engineers, changing forces often took up to an entire shift or multiple hours when several lines of another car model had to be set up. With the use of modular tooling, this time was shortened to less than thirty minutes. Namely, this is achieved through the design of the tools, that is, their holders, cutting heads, and even spindles could be quickly switched while requiring minimal adjustment.

Materials and Components

Another aspect of the system’s versatility is the ability to process multiple materials and component sizes by a single setup, which can be crucial in industries such as aerospace. In their study, a market leader in aerospace manufacturing indicated that their tooling inventory was cut by more than 50% after the introduction of modular systems. The production capacity also remained unchanged, meaning that they could process the same materials, such as medium-thickness aluminum and steel, with the same setup.

Modules can be used in Other Machines

Moreover, these tools are not only versatile across multiple applications but across CNC machines. To clarify, the same tooling can be used in a milling, lathe, or a grinder, significantly reducing the necessity for a given machine in the shop to have its own separate tooling. In their respective study, a job shop indicated that the transition toward full modular tooling allowed them to use the same setup with both machines they have of differing brands and capabilities. Both their machinists and CNC equipment operators underwent training, which substantially improved the utility of the machines and minimized downtime. Notably, these modular systems also quickly adapt to advances in CNC technology, such as sensors for predictive maintenance or automatic adjustment. The manufacturer noted that they implemented similar technology to an extent with the development of a module which uses real-time parameters to near-perfect precision of parts with complex geometry.

Effective Cost Savings

The CNC modular tooling system facilitates lower manufacturing costs through a number of mechanisms, with lower tool inventory, less downtime, and enhanced tool use efficiency being the primary among them. These cost savings are observed in industrial environments where production flexibility and pace are important.

Lower Inventory

The principal of how modular tooling systems save costs is the reduced need to hold a large tool inventory. Traditional set-ups often require a specific tool for a specific job while modular systems use parts that can be repurposed and refitted for any given job. A machining plant was able to reduce tool inventory costs by 40 percent after switching to a modular system. The speed of output remained the same, implying that the number of unique tools in the inventory required for the same quality of output decreased.

Less Downtime

Modular tooling systems also save costs through less downtime between production jobs. Assuming a CNC operation that required one hour of machine downtime for a complete tool changeover, modular tooling could achieve the same in as little as 10 minutes. This means that the time the machinery stands idle is reduced by 50 minutes for every job, and the overall machinery use increases proportionally.

Longer Life

Consequently, tools used in modular systems also last longer. Their precession settings allow them to operate at nominal conditions, which results in less wear on the tools. As an example, a heavy machine manufacturer witnessed an addition of up to 30 percent of life to the tools it used on production lines after adopting modular tooling. The company was able to reduce tool replacement costs and the amount of tools consumed per product unit. The maintenance process is also streamlined. Standardized maintenance care for modular systems is simpler. There are less different kinds of tools in the production line, and all the bits and pieces that go into production are standardized and easier to maintain and care for unlike a diversity of specific tools in a non-modular system that require specific care. A tech company was able to achieve 20 percent less in annual CNC machine maintenance costs with modular tooling.

Improve Tool Durability

CNC modular tooling systems are developed specifically to limit frequent tooling replacement costs and improve the durability of tools, which is guaranteed to improve the quality of manufacturing. Due to the design and integration of CNC modular tooling systems, there are several advantages that can be considered to elongate tool life, especially in high-demand manufacturing settings.

The Use of the Tooling

The basic concept behind the tool life of tooling when using it in modular establishments is the use of the tool. Since the system provides accurate tool positioning and fastening, the vibrations during the tool operating are minimized. With the perfect use of tooling in the system, major automotive part manufacturer observed a 25% increase in turn life since perfect tool alignment was reached, and tools were then properly secured in the modular setup, which was required to minimize the stress points tooling is subjected to and prolong the life of the tool by reducing the wear it faces regularly.

The Material Tooling Is Made Of

Throughout the work process, it is much easier to swap for the different material the tooling is made of. This can greatly affect the life of the tool. For example, switching to diamond-tipped tooling while cutting the abrasive materials will greatly increase the durability of the tool. The use of hardware that is suited to the product will bring positive changes to the tooling since the life of cutting Ceramics Processing Facility’s tools was increased by 54.2% due to the coverage being made of a material that is specific to the work piece’s hardness and abrasiveness.

The Stress the Tool Is Subjected To

Due to the adjusted system of toold holders and collets, there is a variation of the amount of stress of both thermal aspect and another stress the tool is regularly subjected to. During the managing of the tool, it is far easier to dissipate the heat and distribute the thermal force more evenly. During the high speed machining of aerospace components, the lifetime of the tools was never limited by the heat that was created. With the tooling holders arranged in a modular system allowed the force to be distributed evenly and dissipated the heat faster. The overall life of such tools was increased by up to 30%. The regular maintenance intervals symptom incorporated into a valuable tech production line at a certain pivot point, where the modularity of the system require that such intervals would be realized alongside the above-mentioned checks and fine tunings.

Simplify the Setup Process

CNC modular tooling systems have greatly simplified the setup process in manufacturing. This is vital to reducing setup times, minimizing the probability of human error and increasing productivity. The following real-word examples across different industries will explain how modular tooling systems dramatically reduce the complexity of the task of setting up the machine.

Time Reduction

First and foremost, modular product families have greatly reduced the time required for specific machine setups. For example, a precision engineering firm had a setup that used to take many hours: by switching to the modular tooling system, they decreased setup time to less than an hour. Many of the essential components, such as the basic toolkit, were pre-configured using the modular approach. Hence, the most time-consuming part of the setup – adjustments – were omitted, making the setups quick and easy and allowing swift changeover between the production runs.

Standardization

The modular tooling systems are highly standardized, which simplifies the design. For instance, an automotive parts manufacturer fitted all CNC machines in their workshop with modular tooling. Hence, all the setups were standardized, thus eliminating the need for complex training processes and allowing the operators to work with any given machine. The thing that made modular systems a possibility is the automation of the setup and the alignment process: these systems can automatically determine how to align each module.

The industrial equipment producer highlighted another advantage of using the modular approach: the manufacturer reported zero incidents related to incorrect setup. The tooling was brought down and set up outside of the machine, then the parts from the modular system were arranged. This approach allowed the workers to avoid the possible incorrect measurements and adjustments that occur when trying to align the parts inside of the machine.

Adaptability

When the non-consumer electronics producer introduced a new product design, they used an excellent thing about modular setup. The tools were simply rearranged to form a point suitable for the new product, with little downtime. The manufacturer was once again able to quickly adapt in response to the competitive pressure that forced the company to introduce a pre-manufacturing period.

Ergonomics and Safety

Finally, the use of modular equipment in setup greatly facilitated the implementation, in particular for ergonomics and safety concerns. The parts are lighter and have ergonomic handles, thus reducing the physical strain on the operators. Additionally, the facts of incorrect assembly are greatly reduced, thus reducing the number of workplace accidents. The plant manufacturing aerospace components reported fewer injuries during setup due to this design.

Seamless CNC Integration

Comparability with Existing Machinery

CNC modular tooling systems are specifically designed with compatibility in mind gaining the maximum out of currently available CNC-compatible machinery. For instance, when a machine shop was asked to compare their experience of operating both vintage CNC machines from 2002 and the recent modular tooling system developed in 2019, it turned out that the latter was able to boost machine capacities of the old machine without any investment into a new one — something that can be attributed to a universal interface allowing to fit any spindle types, control systems, etc.

Ease of Installation and Configuration

Another important feature is that modular tooling systems are in most cases delivered in a state that precludes any initial adjustments and allows the operator to install and configure the system in the shortest terms without any special training. For example, a small automotive parts manufacturer considered it important to deploy a modular tooling system strictly within the weekend and was able to resume confidently on the very next Monday morning.

Software Integration

Another advantage that simplifies the use of CNC modular tooling systems is that the software is in most cases integrated with a previously installed CNC machine software so that operation of the system and the software goes hand in hand without any impediments. Improving the process of machining by integrating tooling software, the major aerospace manufacturer automated data flow between the CNC operations and the tooling system, which also significantly reduced material scrap rates.

Scalability

Naturally, scalability is another aspect when it comes to compatibility with existing installations. Therefore, when an electronics assembly company that had already used scalable modular units for 2 years, they were able to double up the output by adding more units to its existing modular set stopping otherwise unnecessary investments into more complete CNC machinery.

Support for Tool Changes and Other Features

Finally, seamless integration with existing CNC machinery is crucial for tool change automation and predictive maintenance that allows for extensive slope forming with long-lasting tools. In our practice, a manufacturing plant used modular tooling in the frameworks of their two CNC machining systems since two years ago managing not only to automate the long and labor-intensive process of tool wear detection for manual replacement but also to completely eradicate problems with chip management in their newly acquired equipment.