CNC machining provides high precision (0.0001 inches), material versatility, quick production times, consistent repeatability, and cost-effective low-volume production

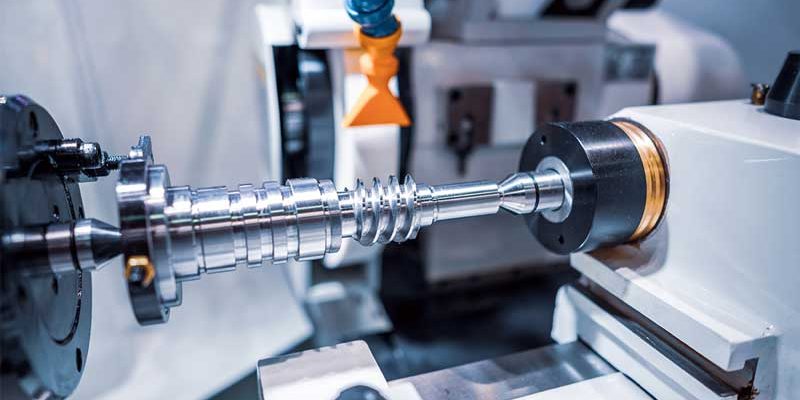

High Precision and Accuracy

CNC machining is world-renowned for its exceptional precision and accuracy. Unlike most other manufacturing methods, CNC machining processes provide the degree of accuracy necessary for many complex parts. Most CNC machine shops maintain tolerances as close as 0.0001 inches. Exceptional precision is often vital in industries where the smallest parts and shapes have the greatest significance. For example, in the aerospace industry, construction or repair of jet aircraft depends on the part precision.

Aerospace Industry:

In the aerospace industry, gas turbine works consist of incredibly hot and high-speed airflow. Consequently, turbine blade construction thresholds are highly stringent to ensure safety, performance, efficiency, among other parameters. Any deviation can affect the safety, energy efficiency, or engine performance. Thus, CNC machining plays a significant role in turbine blade manufacturing.

Medical Devices:

In the medical sector, the precision is equally important. Implants must be safe and function the right way. The manufacture of surgical instruments, implants, and diagnostic equipment parts should also be up to standard. Titanium is a popular material for implants in dentistry, orthopedic surgery, and other medical fields. The material is biocompatible and strong. Titanium is also hard, which makes it hard to mill manually. However, CNC machines are capable of working with the material given specific instructions and guidelines. They can also easily shape titanium using CNC processes to give it the form needed to produce joints or dental implants.

Automotive Industry:

In the automotive industry, the engine is a sophisticated set of parts that must work the right way. Piston construction provides a good case study for part precision in construction. It accommodates needs for motor guarantees high-speed automotive performance. The parts of all single-cylinder turn complex engines include pistons and cylinders. CNC machined pistons and cylinders fit exactly so as not to cause leaks and engine failure.

Precision Accomplished

CNC machining is characterized by the high precision and accuьзкуюжж-Y##, which can be achieved due to computer control. Computer guidance allows obtaining exceptional detail. CNC machines follow the design instructed by computers, which includes every aspect. Every step is followed by CNC machines. For instance, machines define the speed of cutting tools. Instructions also apply to CNC machine feed rate. Quality inspection is also conducted with metrology machines, including Coordinate Measuring Machine to ensure that required tolerances have been met. Real-Life Impact

High precision in part manufacturing has a profound effect on product quality. It ensures that parts fit other parts they are supposed to fit. Products also operate more smoothly and last longer. In industries, where human life and health depend on proper tool performance, the preciseness obtaining became a modern savoir-fare. However, the detail in CNC machining affects the quality of products not only in terms of their operational performance but also regarding the products overall high quality. As a result, every customer is better satisfied with product acquisition.

Material Diversity

CNC machining offers wide material diversity that enables engineers and manufacturers to work with a broad array of materials. The following list highlights the materials it is most effective for, and the reasons for their application:

- Metals:

CNC machining is considered highly effective for working with metals, thus it is preferred by industries requiring robust and reliable components. Metals workable with this method include aluminum, steel, titanium, and brass. Aluminum is popular due to its low density and corrosion resistance, while steel is widely used because of its toughness and durability. At the same time, titanium benefits from its biocompatibility and strength, so it can be found in medical implants and aircraft parts. Here, CNC machining allows it to create workpieces with the needed quality, such as bone screws or airframe components.

- Plastics:

Although its durability and other characteristics are inferior to other workable materials, such as metals, and composites, plastics must be worked with primarily due to their light weight and corrosive resistance. Workable plastics include ABS, polycarbonate, and nylons: the first is known for its toughness and impact resistance, it can be found in housings and brackets of consumer electronics and automotive parts. Polycarbonate is used due to its high impact strength and clarity, such as the required qualities of safety gear and optics. Finally, nylong is commonly used in gears and bushings found in industrial equipment, combining the strength and wear resistance qualities: all of these important properties are achievable, largely due to CNC machining capabilities, which ensure tightness of the tolerances of these parts, as well as smoothness of their surface finish.

In conclusion, CNC machining can be used to work with a wide variety of materials, crucial for creating parts with the required array of qualities.

- Composites and Exotic Materials:

CNC machining applies to a variety of composites and exotic materials, offering solutions to particular applications.

- Carbon Fiber Composites :

Carbon fiber composites are mainly used for their high strength relative to the weight. These composites are widely used in aircraft and aerospace manufacturing. Similarly, carbon fiber composites are used in sports materials due to the lightweight and strong nature of the materials. The strength of the carbon fiber composites relative to their weight is highly beneficial for sports equipment. CNC machining can be used to reduce, drill, process, and create carbon fiber composites accurately, investing and securely.

- Fiberglass :

Fiberglass and other laminates are used in electrical and structural materials due to their excellent thermal and electrical insulating properties. Electrical circuit boards and insulation panels may also need to be highly precise. Accurate CNC machining can be used to shape and mill fiberglass and other laminates into the tightest tolerance products possible

- Exotic Alloys :

High-temperature and highly corrosive environments can tolerate certain exotic alloys, such as Inconel and Haselloy. More parts for these specific applications are developed, many of them becoming more complex. This makes it even more important for the construction of parts to be accurate, highly durable, and high tolerance.

- Wood:

To achieve intricate designs in both furniture and cabinetry, CNC machining tools can create detailed wood components. Woodworking can produce highly detailed and regulated musical instrument components. CNC routers also allow for the efficient cutting, carving, and engraving of wood, enabling the production of highly complex patterns. The Engineering Process (November, 2021). CNC Machining of Exotic Materials. Manufacturing.

Quick Turnaround Time

CNC machining boasts the most significant benefit, which is the ability to reduce manufacturing lead times substantially. For many modern industries, speed is crucial and may determine the business success. There are at least three critical aspects that help in the context of CNC machining.

Efficiency of Programming and Setup

The process of transforming a design of something into a physical part is rapid if the practice refers to CNC machining. Typically, an already existing model made in CAD/CAM can be immediately turned into a CNC program using CAM software. The latter feature eliminates the need for making manual drawings and writing instructions. Moreover, as compared to traditional machining, the setup time is virtually nonexistent. Setting up a machine for a new process can take up to a few hours on a CNC mill or lathe, while in case of traditional tools, it may take days. In other words, in the former case, the time taken to get a new job started is spent on creating the program only.

Rapid Prototyping

Quick fabrication and transformation of a new idea into a physical part is something that many industries can take advantage of by using CNC machining. In such times, it is one of the keys to gaining higher market share. Looking at the high complexity of a part, it can be seen that the practice is beneficial. When it takes weeks to machine a complex part with traditional methods, with CNC machining, it can be achieved in just a few days – meaning a reduced engineering time spent, as well as a reduced time for final part testing. Moreover, the setup makes it easy to try hundreds of variations of a product in a very short period of time.

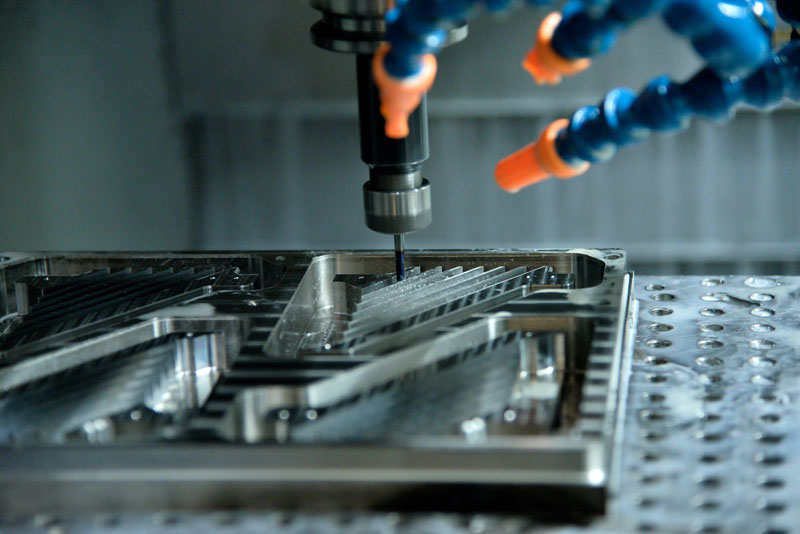

High-Speed Machining

CNC Machines have high-speed spindles that help in speeding up the machining process. Also, since the cutting tools used are sharp, the duration needed for machining gets significantly reduced. For instance, CNC milling machines have spindle speeds of up to 20,000 rpm, which facilitate the machining process. High-speed machining not only shortens the manufacturing lead times but facilitates the process of part production.

Automated Tool Changes

CNC machines are equipped with automatic tool changers that can change between different cutting tools without requiring manual input. The ability to automate this process can reduce downtime between operations significantly, as a CNC machine can switch between a milling tool and a drilling tool in seconds. This means that the machine never has to wait for tools to be changed, allowing for efficient and continuous production. Overall, the ability to automate tool changes can make the manufacturing process more streamlined and reduce the time necessary to produce parts.

Simultaneous Multi-Axis Machining

Advanced CNC machines can perform multi-axis operations that allow for all of the machine’s axes to be moved at the same time. It means that complex geometries can be machined in a single setup, reducing the time needed to produce a part and producing more accurate results. A 5-axis CNC machine can be used to machine a part with undercuts and complex geometry in a single setup, whereas other types of machines might require moving and re-clamping parts many times. Simultaneous multi-axis machining allows for parts to be produced in a single cycle, maximizing precision and allowing for complex geometries.

Minimal Downtime

CNC machines are designed to be highly reliable and require minimal maintenance. They can operate for long periods of time continuously, with planned maintenance intervals being measured in months. Additionally, CNC machines can be set to perform unattended machining, where they will run a pre-programmed cycle without requiring a machinist’s attention. In this way, the machine can be set to produce parts overnight in case the workshop has two shifts but is still closed for the night, reducing overall lead times.

In the example of the consumer electronics industry, speed to market is one of the critical advantages of CNC machining. Considering the short life cycles of the products and the high demand on the market, fast turnaround times are vital for companies. For example, one of the companies working on the new models of smartphones can use this technology to produce and test prototypes, make necessary adjustments, and begin the mass production of the new model on the market in several weeks instead of months or a year required. The ability to meet present demand as soon as possible is one of the most significant advantages on the consumer electronics market.

Consistency and Repeatability

CNC machining is widely considered as a technology that can produce parts with high consistency and repeatability – and both of these aspects are critical for any kind of the production, especially in the industries that require precise and reliable components. Basically, every implementation of a CNC machine allows achieving the same part multiple times. Usually, the part will be identical in dimensions, material, surface, structural strength, etc. All of these properties would be crucial to ensure that the final product is consistent in quality. Below, this paper lists three factors that contribute to the high level of consistency and repeatability.

Precision Engineering

Basically, CNC machines are controlled with the help of computer programs that are specifically written and bound to follow exact instructions. Because of the nature of these computerized procedures, the CNC machines can use the most precise engineering methods to produce the parts. Indeed, the majority of CNC machining executions achieve extremely tight tolerances and can maintain them easily. For example, there are CNC systems capable of maintaining tolerances as fine as 0.0001 inches. Also, every single part will be machined according to the exact same specifications. This way, all parts will remain identical. In many industries, measuring equipment for non-standard parts is out of use, so any deviation of any kind will draw severe attention. For example, a blade of an aircraft engine might just be a few microns too short or too long to function correctly. Scientific and medical industries also require parts to be of high precision.

Automated Processes

Since the process is automated, most of the variable and uncertain factors that are involved in manual machining are all across the board, and once the program and design is in – the master that would produce the part is outside of the equation. In other words, human factor is not involved in the production process. This results in a situation where all parts are produced under the same conditions with no random variables. Also, in many CNC systems, automatic quality control systems check the quality of every produced part and reject those parts that do not match the quality requirements.

Repeatability

NC machining allows replicating the same part over multiple production runs with a great degree of accuracy, which is especially important for large-scale manufacturing. For instance, in the automobile industry, hundreds of thousands of engine blocks and transmission parts need to be produced at precise specifications. Using CNC machines guarantees that each part is identical to another one, which is vital for the performance of a vehicle. Therefore, the ability to run repeatable production runs is vital for the production of various products ensuring that they function as intended. Overall, this is one of the most important advantages of CNC machining, as it ensures a high level of precision.

CNC machining is also advantageous due to its advanced software capabilities integrated into the machines, which allows an easy transition from the design phase. First of all, the software ensures the precise translation of all design decisions in the production process, meaning that each part is identical to the design. Secondly, it minimizes the possible mistakes that could potentially be made by an operator. As a result, it ensures a high degree of precision, which is crucial for the overall performance of a product and making sure that each product is identical. Overall, using advanced software is one of the other most important advantages of CNC machining.

Small Batch Production is Cost-Effective

An important benefit of CNC machining is, of course, its cost-effectiveness for small batch production. Thanks to this method, manufacturers can quickly produce high-quality parts in any amount. Anyway, most machining manufacturers allow doing the job fast and tight and producing a small number of precise parts. The quality of the produced parts is no less high, even in small batch production. CNC offers the opportunity to process a single prototype part, a dozen units, or even 100 units in the most demanding materials.

Low setup costs

Compared with injection molding or casting, there is no need for expensive molds or moldings, making CNC machining most cost-effective in small production batches. The low setup costs time, and money for both work and machine make this process more attractive for startups or companies looking to cut costs for small and medium-sized batch production.

Flexible production runs

The CNC machining process involves using computer programming to control the spindle and other cutting tools. The technology offers maximum order flexibility. CNC machines could easily produce any number of the part you need, which is relevant for the supplier and customer that needs one custom piece or a small batch production.

Quick turnaround time

In the case of a small production batch, the turnaround time is also minimal with CNC machining. The programmed process is as simple as the installment of the work job making sure the future part is placed properly under the spindle machine. Therefore, the CNC machining process is one of the fastest ways to produce a small number of parts. For example, the batch of 50 pieces is done within 2-3 days instead of 2-3 weeks or even months for other production methods.

Reduced waste

In the case of CNC machining, the waste amount is relatively minimal, as this is a subtractive production method. The process is programmed for minimizing these products and spares using the most advanced tools of software and toolpaths.

Economies of scale

While CNC machining is the best option for small batch production, it has benefits from scale economies. Increasing the number of produced parts reduces the cost of their manufacture in proportion. For the company producing bicycle components, it wants to test the market and produces 200 parts of a new model. However, for these specialists, there are no costs for molds and casting tools, which allows starting the process of part production at the lowest cost that is possible with CNC machining.